The product information about NVF3-11/TS4

The Chint NVF3-11/TS4 frequency inverter is a widely used electronic power device for controlling the speed of three-phase motors. With a power rating of 1.5kW, this inverter offers high efficiency and reliability in both industrial and domestic applications.

Key components of the inverter system include:

Rectifier: Converts three-phase AC voltage into DC voltage.

Filter: Removes noise components in the current.

Inverter: Converts DC voltage into AC voltage with adjustable frequency and amplitude.

Controller: Manages the voltage and frequency conversion process to meet motor requirements.

1. The product overview of NVF3-11/TS4

Nominal power: 17 KVA (Kilovolt-amps)

Nominal input current: 26 A (Amperes)

Nominal output current: 25 A (Amperes)

Motor compatibility: 11 kV

2. The technical specification NVF3-11/TS4

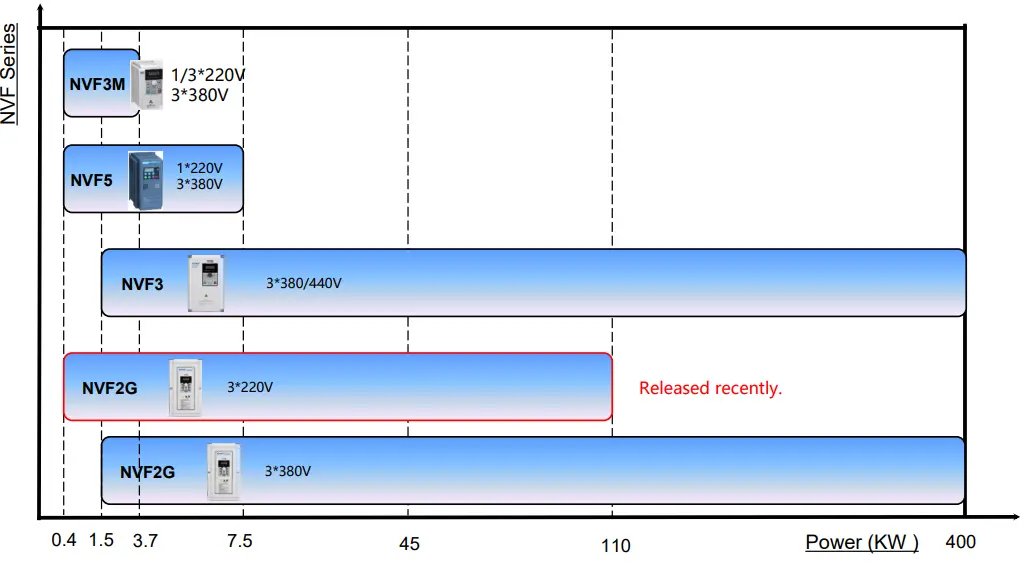

3. Product life cycle NVF series

4. The ordering information NVF series

5. Outstanding features inventer NVF3-11/TS4

Vector Control: The vector control technology enables the inverter to achieve high precision in controlling motor torque and speed, especially at low speeds.

Overload Capability: The inverter has a high overload tolerance, ensuring stable operation under harsh working conditions.

Easy Installation and Use: With a user-friendly interface and many preset functions, the NVF3-1.5/TS4 inverter is easy to use, even for beginners.

Energy Savings: Thanks to advanced control algorithms, the inverter helps minimize power consumption, contributing to reduced operational costs.

High Reliability: Manufactured using modern technology, the NVF3-1.5/TS4 inverter is durable and has a long lifespan.

6. NVF3-11/TS4 in deployment fields

Motor Speed Control in Equipment:

Conveyor Belts: The inverter helps adjust the conveyor speed precisely, tailored to the type of product and production requirements. This ensures smooth goods transportation and prevents product damage or dropping.

Pumps: The inverter regulates the flow rate and pressure of the pump, adapting to varying water usage needs. For example, when water demand decreases, the inverter automatically reduces the pump speed, helping to save energy.

Fans: The inverter adjusts the airflow and pressure of the fan, meeting different cooling or ventilation needs. This results in a more comfortable working environment and energy savings.

Industrial Automation:

Production Line Control: The inverter is used to control the speed of motors in the production line, helping synchronize processes and improve production efficiency.

Robot Control: The inverter controls the joints of a robot, enabling precise and flexible movements for performing various tasks.

Packaging Machinery:

Packaging Speed Adjustment: The inverter controls the speed of motors in packaging machines, ensuring products are packaged quickly and accurately.

Process Synchronization: The inverter helps synchronize various packaging stages, such as feeding, sealing, and printing dates, ensuring smooth and efficient operation.

7. Catalog NCF series