What is an inverter? What is its structure and operating principle? Applications of inverters in life - How to choose the right inverter... Join Amazen to find out all the information about inverters through the article below!

1. What is an inverter?

An inverter is an electronic device or circuit that converts electrical energy from direct current or alternating current at this frequency and phase configuration into alternating current with this frequency and phase configuration. other phase. The inverter can change frequency from 1Hz to 50 Hz or up to 400Hz with CNC high-speed motors. Inverters are widely used in industrial applications to control motor speed, reverse rotation, reduce starting current, reduce vibration and save energy.

Or to put it another way: An inverter is a device that changes the frequency of the electric current applied to the coil inside the motor and through that can control the motor speed steplessly, without needing to use gearboxes. mechanical. The inverter uses semiconductor components to sequentially turn on and off the current applied to the motor's coils to create a rotating magnetic field to rotate the motor. Inverters can adjust motor speed from slow to fast depending on the specific application, helping the motor operate more efficiently.

Image of inverter

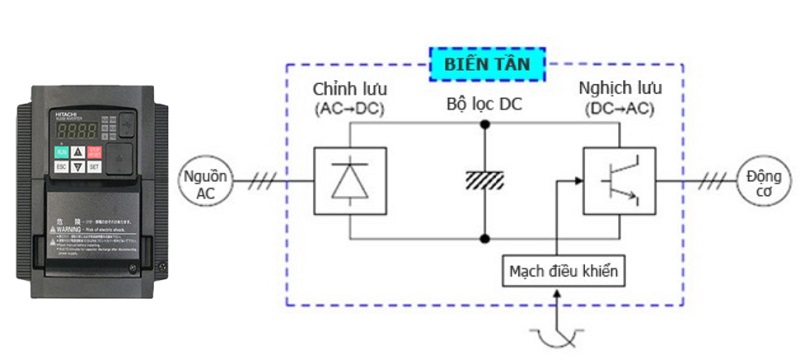

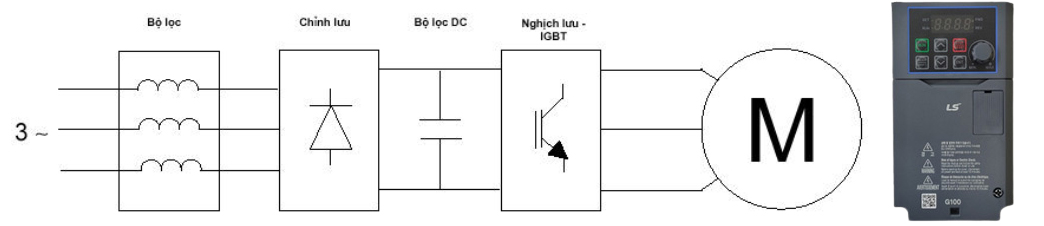

2. Structure of the inverter

The inverter is made up of components that have the function of receiving a power source with a fixed input voltage and a fixed frequency, thereby converting it into a power source with a controllable three-phase variable voltage and frequency.

Some main parts:

- Rectifier: The first part in converting the input voltage to the desired output for the motor is rectification. This is achieved using a full-wave diode bridge rectifier.

- DC Bus: The DC bus is a capacitor bank that stores rectified DC voltage. A capacitor can store a large charge, but arranging them in a one-way conduction configuration increases the capacitance. The stored voltage will be used in the next stage when the IGBT generates power for the motor.

- IGBT: IGBT devices are recognized for high performance and fast switching. In the inverter, the IGBT is turned on and off in sequence to generate pulses of different widths from the dc bus voltage stored in the capacitor.

- AC reactor: The AC reactor is an inductor or coil. The inductor stores energy in the magnetic field created in the coil and resists changes in current.

- DC reactor: DC reactor limits the instantaneous rate of change of current on the DC path. This reduction in rate of change will allow the actuator to detect potential problems before failure occurs and disengage the actuator.

- Braking resistor: The excess electricity generated needs to be handled somehow. The resistor is used to quickly “burn off” this excess electricity generated by this phenomenon by converting the excess electricity into heat.

Structure of the inverter

3. Operating principle of the inverter

- In general, the basic working principle of the inverter is quite simple. First, the single-phase or three-phase AC power source is rectified and filtered into a flat DC source. This step is performed by a diode bridge rectifier and capacitor. Thanks to that, the cosphi power factor of the inverter system has a value regardless of the load and has a value of at least 0.96. This DC voltage is converted (reversed) into a symmetrical 3-phase AC voltage. This step is currently performed through the IGBT system (isolated gate bipolar transistor) using the pulse width modulation (PWM) method. Thanks to the advancement of current microprocessor technology and power semiconductor technology, the pulse switching frequency can reach the ultrasonic frequency range to reduce motor noise and reduce losses on the motor iron core.

- The power conversion efficiency of inverters is very high because they use power semiconductor components manufactured using modern technology. Thanks to this, the energy consumed is approximately equal to the energy required by the system.

- In addition, today's inverters have integrated many different control types suitable for most different types of loads. Nowadays inverters have integrated PID and are compatible with many different communication standards, very suitable for control and monitoring in SCADA systems.

4. Classify inverter lines according to voltage

AC inverter

Single-phase inverters and three-phase inverters using AC voltage are widely used in factories. It can be said that more than 90% of inverters are of this type.

DC inverter

This type of inverter controls the branching of a DC motor. This design of a DC motor separates the induction section and the bypass circuit.

With this type, the output switches generate a new sine wave for the electric motor's voltage by inputting a series of square waves at different voltages. Inverters of this type often work with the support of a large capacitor.

1 phase inverter

Also known as 1-phase to 3-phase inverter. To make buying and selling more convenient, people often call inverters abbreviated. For example, a single-phase inverter. This refers to the type of inverter whose input voltage is only 1 phase (220V) and the output signal is 3 phase 220V. This name is to distinguish it from the type of inverter with 3-phase 380V input and 3-phase 380V output.

3 phase inverter

The inverter controls the motor speed

As we know, an inverter is a specialized device to control motor speed by changing the frequency of electric current. That is, through adjusting the frequency, we can adjust the motor speed to change as desired in a wide range.

Changing the speed of the motor when using an inverter is also very simple. We just need to adjust the frequency with the inverter and the speed of the motor will change accordingly.

In addition, attaching an inverter to a 3-phase motor also helps the motor start softer, helping to protect the electrical system as well as reduce mechanical shock to the motor. The inverter also helps protect against overload, overvoltage, and overcurrent during motor operation.

Grid-connected inverter

Also known as solar inverter. This is a type of inverter specialized in the field of solar power production.

At this time, people will use grid-connected inverters (or grid-connected inverters) to convert this DC current into alternating current and send it to the load for consumption.

The solar grid inverter will connect to the grid continuously in the morning, giving priority to using solar power. If there is any remaining solar power, it will be pushed to the national grid. Conversely, at night and on days when there is a lack of sunlight, the system will automatically take grid power to compensate for the devices.

The inverter operates completely automatically, the entire system will automatically shut off when it gets dark and operate when the sun comes back.

Elevator inverter

That's why people have to use elevator inverters. This is a type of inverter specifically used for elevators to control the speed of the motor, helping the elevator stop at the desired position.

For elevator inverter types, it uses semiconductor inverters; Flexibility such as automatic motor recognition, control features via network; 16 levels can be set; Controls motor current for smooth (soft) starting; Improve mechanical structural durability.

Low voltage inverter

This is a type of inverter with input of 110V, 220V or 380V. It can be said that this is the common name of all types of inverters on the market today.

Medium voltage inverter

This type of inverter has very large input voltages such as 3-3.3 kV, 4kV, 6-6.6kV, 10 kV, 11 kV. And in Vietnam, systems using this type of inverter are very few.

Medium voltage inverters are applied in industries such as: paper; metallurgy, cement, petroleum, mining, plastic, rubber.

5. Application of inverter

Applications of inverters in industry

Water supply system for high-rise buildings

In the past, water supply to high-rise buildings often relied on pumping water up the tower and then sending water down to each floor, using equipment to adjust the pressure. This method is ineffective and expensive. With inverters, water tower construction costs can be saved.

Ventilators

Exhaust fans are commonly used in equipment such as vacuum cleaners, furnaces, and ventilation systems. Inverters help optimize motor performance, allowing pressure and flow to be adjusted according to need, helping to save energy.

Air compressor system

Traditionally, air compressors often use an open/in method to control air flow. When the pressure reaches its highest level, the machine will stop compressing and when the pressure drops, the machine will start operating again. This leads to inefficient power consumption.

Lifting and lowering system

Drives help optimize position, torque and braking adjustments in applications such as cranes. With the ability to regenerate energy and re-enter the grid, the inverter for the lifting system helps operate safely and save energy.

6. Benefits of using an inverter

- Easily change engine speed, reverse engine rotation direction.

- Significant energy savings compared to direct motor running method.

- Reduces starting current compared to direct starting method, star-delta starting method so it does not cause voltage drop or difficulty starting.

- Inverters often have electronic systems with over-current protection, over-voltage protection and under-voltage protection, creating a safe system when operating.

- The starting process via a low-speed inverter helps prevent large-load motors from having to start suddenly, avoiding damage to mechanical parts and bearings, increasing motor life.

- The inverter is integrated with communication modules, making control and monitoring from the center very easy.

- Thanks to the working principle of inverter conversion through diodes and capacitors, the reactive power from the motor is very low, thus significantly reducing current during operation, reducing costs in installing capacitors, minimizing power loss on the line.

7. Instructions for choosing types of inverters

To choose the right type of inverter for your application, it is necessary to clearly determine the application needs, purpose of use and balance the investment level. To choose the type of inverter that best suits your usage requirements, you should note the following selection principles:

- Choose an inverter suitable for the motor type and motor capacity: find out what type of motor you need to install the inverter, synchronous or asynchronous, 1 phase or 3 phase, DC or AC, voltage how much... to choose the right inverter. The inverter capacity must be equal to or greater than the motor capacity.

- Choose an inverter according to application requirements: when choosing an inverter, you need to clearly determine what your application is? What speed is required? Are there any special advanced control features required? Is there a requirement for system synchronization or communication? Are there any characteristics of the working environment that need attention (humidity, high temperature, lots of dust, flammable and explosive...).

- Choose an inverter according to the actual load: Choosing an inverter according to the load is very important. The first thing is that you must determine what type of load the machine is: light load or heavy load, average load and whether the operating mode is short-term or long-term, continuous or intermittent... from there choose the type. suitable inverter.

- Choose an inverter that is convenient for programmers when programming controls or choose a supplier capable of supporting the programming of your applications.

- Select the inverter according to the specifications of the old inverter (in case of replacing another brand) or according to the required design specifications.

- And finally, don't forget to consider financial factors. For peace of mind, choose a reputable and popular inverter on the market, with a good warranty, stable and durable product quality, and quick and dedicated repair and customer care services.

8. Top popular inverter brands in Vietnam

LS inverter

Among the types of inverters on the market today, it is impossible not to mention the LS brand. LS is a brand from Korea, established in 1974. LS inverters are produced in 9 different series. Each series will have different usage characteristics to suit each customer's needs and electrical circuits. With a reasonable price, high durability, and stable quality, LS inverters are widely used in industrial and civil fields.

Schneider Electric is a global corporation headquartered in France, a pioneer in digitalizing energy management and automation for sustainable and efficient development.

With a presence in more than 100 countries globally, from simple products such as household electrical switches to complex operating systems for high-rise buildings and data centers. , infrastructure and industry, Schneider Electric always provides effective solutions to help customers manage energy and production-business cycles safely and reliably thanks to the integration of energy technologies. world-leading quality and processes. Therefore, Schneider Electric inverters have received a lot of attention and choice from users since their launch.

INVT's multi-purpose, specialized, medium voltage and explosion-proof inverter lines with voltage range from 220V ~ 10kV, capacity from 0.4kW ~ 10,000kW control synchronous motors, asynchronous motors and integrated servo Many advanced, high-performance, smart and energy-saving features are available. Therefore, INVT inverter is an unmissable choice among all types of inverters on the market today.

INVT is one of the world's leading technology corporations in the field of manufacturing inverters, automation equipment and electric energy. INVT has 12 research and development centers with more than 1,300 inventions and 220 software copyrights on inverters - automation and renewable energy.

Refer to inverter products at: https://amazen.com.vn/bien-tan/invt.html

Danfoss inverter

Danfoss was founded in 1933 in Denmark. With more than 80 years of operation, Danfoss is currently a trusted inverter brand in over 100 countries. Danfoss inverters have a diverse product range, modern designs and meet international standards. Many customers have been very satisfied when using Danfoss inverters because of their stability, ease of use, many support functions and especially less interference.

Siemens inverter

Siemens is a brand from Germany and a leading provider of efficient power transmission solutions. Siemens pioneers infrastructure, automation, drive and software solutions in the industrial sector.

Siemens Vietnam was established in 1993. Siemens currently has three offices in Hanoi, Da Nang and Ho Chi Minh City along with an electrical busbar factory located in Binh Duong province. As one of the leaders in inverter technology in the world, Siemens constantly improves and diversifies products to bring the best solutions to users. With diverse models that can control basic to medium tasks, streamlined hardware design and functions, Siemens SINAMICS inverter lines are highly reliable and an economical choice for various applications in industry.

.jpg)

Hitachi inverter

Hitachi is an international company headquartered in Chiyoda, Tokyo, Japan. Hitachi is one of the manufacturers that always applies the most advanced technology to its products. Hitachi inverter with high-end design and energy saving advantages, this is also one of the most popular inverter brands in Vietnam.

Delta inverter

Delta is a fairly popular inverter brand in factories and workshops in electrical systems or machine automation.

This is an indispensable product in a number of industries, factories, and electrical systems that operate machinery. The biggest application is speed control of motors using 3-phase current.

Popular Delta inverter lines: Delta VFD-L inverter, Delta VFD-S inverter, Delta VFD-EL inverter, Delta VFD-M inverter, Delta VFD-E inverter, Delta VFD-CP2000 inverter, Delta VFD-C2000 inverter,…

Mitsubishi inverter

Mitsubishi Electric is a famous Japanese brand in the production of inverters. For many years, Mitsubishi inverters have been trusted and used very commonly in Vietnam.

Inverter Control Techniques

Emerson inverter (Inverter - Drive - Motor speed controller) has a compact size with outstanding power in control features. With powerful control features, stable quality and reasonable price, in Vietnam, inverters (Inverter - Drive - Motor speed controller) Emerson and Control Techniques are widely used, for applications Control applications: pump, fan, air conditioning, ventilation (HVAC) systems, conveyor systems, elevators, escalators, lifting equipment systems, bridge cranes, derrick cranes, base cranes, tower cranes, factories producing rubber, plastic, cement, chemicals, food, plastic, packaging, printing, paper making...

Reputable place to supply Control Techniques Inverters: https://amazen.com.vn/bien-tan/control-techniques.html

Vicruns inverter

Vicruns inverter has a modern design, affordable price and is trusted by many users in Vietnam.

See more Vicruns inverters at Amazen: https://amazen.com.vn/bien-tan/vicruns.html

9. Notes when using inverter

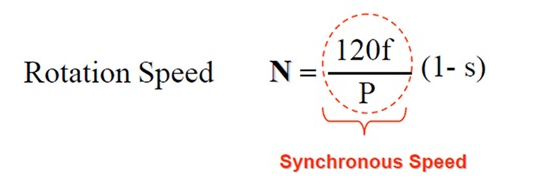

From the above formula we see that there are 3 methods to change the engine speed:

Change the number of motor poles P

Change the slip coefficient s

Change the frequency f of the input voltage

The first two methods are difficult to implement and not very effective. The method of changing motor speed by changing frequency is the most effective method. An inverter is a device used to change the frequency of the power supply applied to the motor, thereby changing the motor speed.

The inverter can change frequency from 0Hz to 400Hz (some inverter models adjust to 590Hz or higher). Therefore, it is possible to make the motor run faster than normal compared to running at 50Hz. For common motors, usually installing an inverter allows adjusting the frequency from 0Hz - 60Hz.

Note:

The first thing you need to do when using an inverter is to carefully read the inverter parameters provided by the manufacturer specifically for each product line, that will help you clearly know how to wire the inverter correctly. To be sure, you should let reputable units with highly specialized engineers install and connect for you. Besides, you need to learn about the additional features of the product such as dust resistance, water resistance, anti-corrosion, emergency stop button, expandability... to safely install, use and maintain the device. and efficiency.

Epilogue

In case you need to learn, need technical advice and order an Inverter, please contact Amazen immediately via:

Hotline: 0934 399 068 - Sales: 0938 072 058

Email: amazen@amazen.com.vn

With a team of highly specialized technical support and sales consultants, our company is confident that it will bring customers the best purchasing experience.

Amazen commits that all inverter products we currently offer are genuine, 100% brand new, quality guaranteed and fully accompanied by certification documents.