1. What is a watertight bridge?

A watertight connector, also known as a watertight relay, is an automatic device used in automatic control systems and industrial automation. Its operating mechanism is based on the principle of sensing water level changes in a specific tank, lake, or water storage area. When the water level reaches a predetermined level, the watertight switch activates and performs an action such as turning on or off a device, usually a water pump or regulating valve.

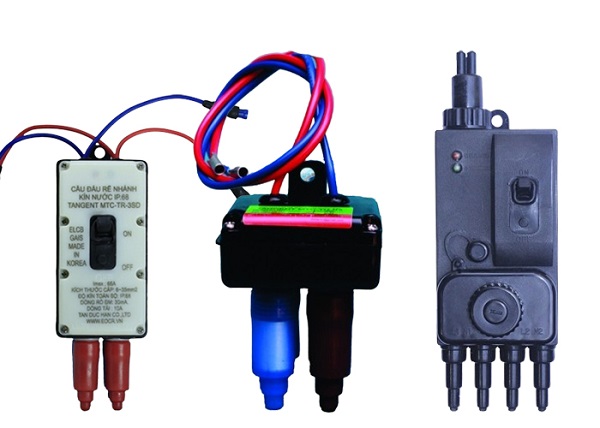

Image of a watertight bridge2. Construction of the Watertight Match

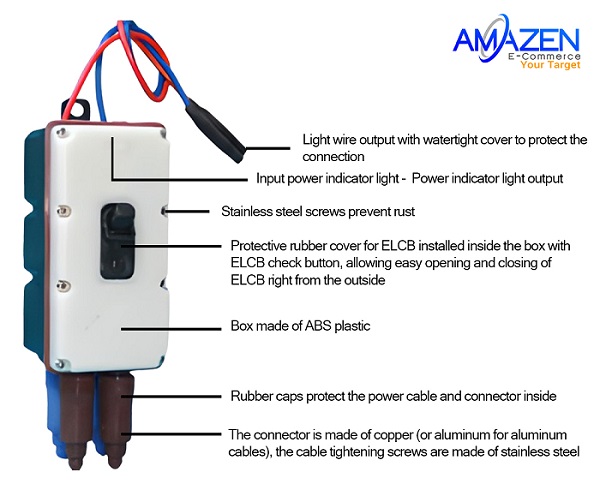

A watertight connector is an electrical device used to connect electrical wires in wet environments or at risk of contact with water. The structure of the watertight bridge includes:

• Housing: Made from water-resistant material such as ABS, polycarbonate or PVC, which protects internal joints from water and dirt.

• Battery: Is the inside part of the terminal, where the wires are connected to each other. The terminals can be made from brass, copper or aluminum, and come in many different forms such as branched terminals, interconnected terminals, etc.

• Gasket: Is the sealing part between the shell and the bridge, helping to prevent water from entering inside.

• Cable: Cable is used to connect the terminal to the power source or other electrical devices.

Structure of watertight bridge3. Operating principle of the watertight bridge

Watertight connectors operate on the principle of insulation and waterproofing. Specifically:

Insulation:

• The conductive parts inside the terminal are made from insulating materials such as plastic, ceramic, etc.

• The wires are connected to the terminal via insulated clips or screws.

• The housing of the terminal is made from insulating material such as ABS, polycarbonate or PVC.

Waterproof:

• The bridge is designed with a sealing gasket between the shell and the bridge, preventing water from entering inside.

• The housing of the bridge is designed to be airtight and can withstand high water pressure.

• The cable is connected to the terminal via waterproof connectors.

Operating principle:

• Wires are connected to the terminal via clips or screws.

• When current flows through the wire, the current will pass through the terminal and reach other electrical devices.

• Watertight connectors help protect electrical connections from water and dirt, ensuring the safety and efficiency of the electrical system.

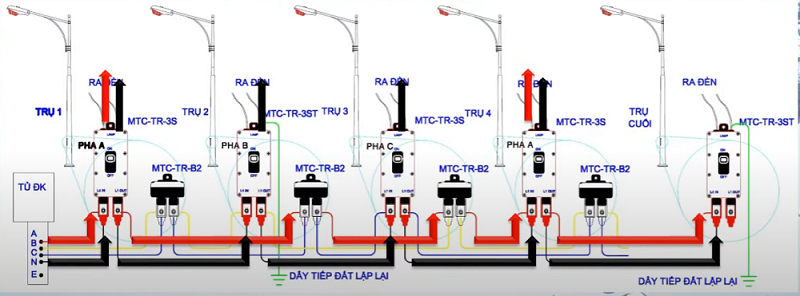

3P 4D network wiring diagram using Tangent MTC-TR-B2 and MTC-TR-3ST watertight connectors4. Application of watertight bridge

Watertight connectors are widely used in many fields such as:

Light:

• Installation in light poles, electrical junction boxes, etc.

• Used for outdoor lighting systems, gardens, and wet areas.

Industry:

• Used in factories, plants, industrial zones, etc.

• Suitable for environments with a lot of dust, chemicals, and high humidity.

Agriculture:

• Used in irrigation systems, water pumping, etc.

• Resistant to harsh weather conditions, erratic rain and sun.

Family:

• Use in bathrooms, kitchens, gardens, etc.

• Ensure user safety, especially in wet environments.

In addition, watertight bridges are also used in a number of other fields such as:

• Solar power system

• Fire alarm and fire fighting system

• Camera surveillance system

• Automatic control system

Some applications of watertight bridges

Below are some specific examples of applications of watertight bridges:

• IP68 watertight connectors are used in automatic irrigation systems to connect electrical wires that carry water to sprinklers.

• IP66 watertight connectors are used in outdoor lighting systems to connect electrical wires to the bulbs.

• IP67 watertight connectors are used in fire alarm and fire fighting systems to connect signal wires to detectors and alarm bells.

5. Advantages of watertight bridges

Safe:

• Protects electric leakage, reduces the risk of fire, explosion and electrical accidents.

• Protect users from the risk of electric shock, especially in humid environments or at risk of contact with water.

Enduring:

• Resistant to harsh environments such as rain, sun, dust, chemicals, etc.

• Long lifespan, less damage, saves repair and replacement costs.

Easy to use:

• Simple installation, no specialized tools required.

• Easy inspection and maintenance.

Aesthetics:

• Neat, beautiful design, suitable for many different spaces.

Wide applicantion:

• Lighting: Install in light poles, electrical junction boxes, etc.

• Industry: Used in factories, plants, industrial parks, etc.

• Agriculture: Use in irrigation systems, water pumping, etc.

• Household: Use in bathroom, kitchen, garden, etc.

In addition, watertight bridges also have a number of other advantages such as:

• Fire resistance: The bridge shell is made from fireproof material, helping to reduce the risk of fire spreading.

• Anti-interference ability: Watertight connectors can minimize electromagnetic interference, helping the electrical system operate more stably.

• Insect resistance: The tight structure of the connector helps prevent insects from entering, protecting the electrical system from damage.

With the above advantages, a watertight connector is a safe, effective and economical choice for your electrical system.

6. Things to note when choosing a watertight bridge

Note: When choosing a watertight bridge, you need to keep in mind a number of factors such as:

• Protection level: IP (Ingress Protection) protection level indicates the water and dust resistance of the bridge. The higher the IP level, the better the protection.

• Number of wires: Choose a bridge with the number of connection ports appropriate to the number of wires to connect.

• Wire type: Choose the appropriate connector for the type of wire being used.

• Size: Choose a bridge with the appropriate size for the installation location.

• You can refer to some reputable watertight bridge brands such as: Sino, Panasonic, Schneider,...

• When using a watertight bridge, you should follow the manufacturer's instructions to ensure safety and effectiveness.

7. Instructions for installation and maintenance of watertight bridges

• Detailed installation steps:

+ Determine installation location: Choose a location to install the watertight bridge so that it is easy to access when maintenance and repair are needed.

+ Installation of infrastructure: Ensure that all necessary infrastructure such as pipes, protective covers, and grounding systems are in place.

+ Electrical connection: Make the electrical connection according to the pre-designed circuit diagram, ensuring compliance with all electrical safety regulations.

+ Testing and commissioning: After installation is complete, it is necessary to check the entire system to ensure everything works correctly, then proceed with commissioning.

• Periodical maintenance instructions:

+ Periodic inspection: Periodically inspect the parts of the watertight bridge to detect possible problems early.

+ Clean equipment: Maintain regular equipment cleaning to prevent corrosion and damage caused by dirt and water.

+ Replace damaged components: Promptly replace damaged or long-used components to ensure the best performance of the watertight connector.

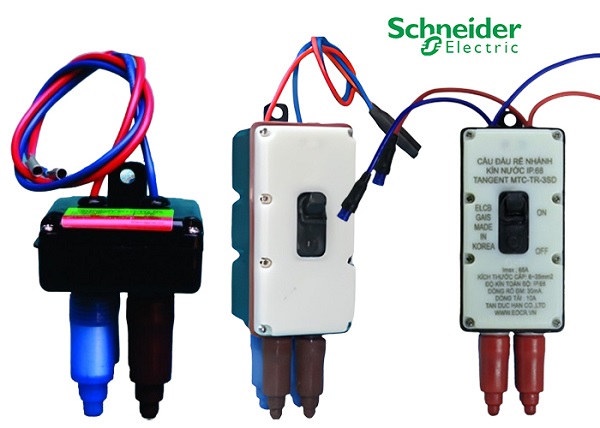

8. Top brands supplying popular watertight connectors on the market

Schneider brand

Outstanding features of Schneider brand watertight bridges:

High Quality:

• Schneider bridges are manufactured from high-quality materials, have high durability, good impact resistance and effective corrosion resistance.

• Electrical contacts are made from pure brass, ensuring good electrical conductivity and minimizing power loss.

Safe:

• Schneider bridge is designed with many safety features such as:

• Tight-tight casing, resistant to water and dust penetration.

• Safe insulating structure, prevents electric leakage.

• Sturdy locking latch, ensuring the wires are securely connected.

Easy to use:

• Schneider bridge is compactly designed, easy to install and use.

• The connection ports are clearly marked, making wiring connections quick and accurate.

Diversity:

• Schneider offers a variety of watertight connectors with different sizes, number of connection ports and protection levels, suitable for many needs.

Good price:

• Schneider bridge has a competitive price compared to other watertight bridge brands on the market.

In addition, Schneider watertight bridges also have a number of other outstanding features such as:

• Fire resistance: The bridge shell is made from fireproof material, helping to reduce the risk of fire spreading.

• Anti-interference ability: Schneider watertight connectors can minimize electromagnetic interference, helping the electrical system operate more stably.

• Insect resistance: The tight structure of the connector helps prevent insects from entering, protecting the electrical system from damage.

With the above outstanding features, Schneider watertight connectors are a safe, effective and economical choice for your electrical system.

Epilogue

Above is all the most important and basic content about the Watertight Bridge product. Hopefully the article content will assist you in the process of learning, choosing to buy and operate this line of automation equipment.

Epilogue

Above is all the most important and basic content about the Watertight Bridge product. Hopefully the article content will assist you in the process of learning, choosing to buy and operate this line of automation equipment.

In case you want to buy a watertight connector and have questions or need further advice, please contact Amazen via:

Hotline: 0934 399 068 - Sales: 0938 072 058

Email: amazen@amazen.com.vn

With a team of highly specialized technical support and sales consultants, our company is confident that it will bring customers the best purchasing experience.

Amazen commits that all glass relay devices we currently provide are genuine, 100% brand new, quality guaranteed and fully accompanied by CO/CQ certification documents.