Limit switches are increasingly used in many manufacturing industries to provide more perfect automation solutions. So what is a limit switch? What types are there and how do they work? How practical is the application? Let's find out with Amazon through the article below.

1) What is limit switch?

A limit switch is a type of electromechanical device used to limit the travel of moving parts in a certain mechanism or system. It has the same structure as a normal electrical switch except that it is equipped with an additional actuator so that moving parts, when impacted, will change the state of the contact inside it. When no longer active, the limit switch will automatically return to its original position.

What is limit switch?

At this point, we can see the difference between travel limit switches compared to normal switches: when activated, they will maintain their state until they are activated again.

Explained in terms of practical application, limit switches are used to detect the presence or absence and determine the movement limits of an object.

Other name

In the automation industry, this device is also called by electromechanical engineers by other names such as travel limit switch, limit switch or limit switch, ...

Symbols in technical drawings

In technical drawings, travel limit switches have symbols similar to those of conventional switches. In the drawing below are the symbols for normally closed pins (NC) and normally open pins (NO).

2) Structure and operating principle of Limit switch

2.1) Structure

A limit switch will be composed of the following parts:

Transmission receiver

The transmission receiver plays an extremely important role in a limit switch. This part is what makes the difference between Limit switch and regular switches. They are mounted on the top of the limit switch and perform the task of receiving impact from moving parts to activate the switch.

Switch body

The limit switch body contains an electrical contact mechanism, including components located inside a plastic shell, which functions to minimize damage caused by impact to protect the electrical circuit inside the switch.

Connection pin (Socket/Pin)

The connection pin is where the screw terminals of the contact are located to connect to the wiring system. This is considered the output signal part for the switch because it is responsible for transmitting signals to other devices when affected by a certain transmission part.

2.2) Operating principle

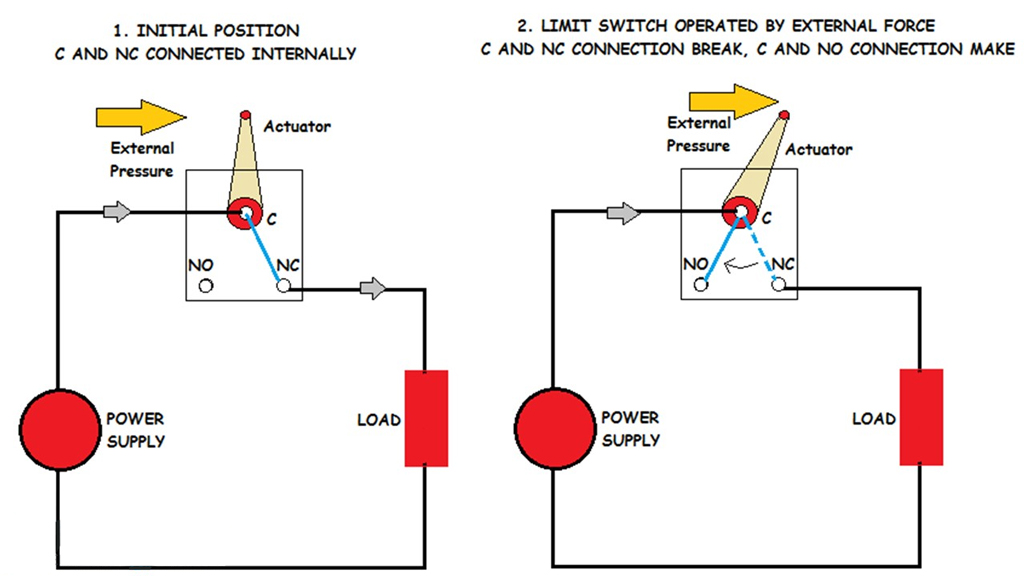

Above is the principle diagram of a common limit switch.

Based on the diagram, the operating switch includes an operating lever, COM pin, normally open pin (NO) and normally closed pin (NC).

Regarding operating principle: In normal conditions, the contact between the NC pin and the COM pin is connected to each other. When force is applied to the lever, the contact between the COM + NC pin is open and switches to the COM + NO pin.

To put it simply, in resting conditions, after electrical connection and no object impact, the COM and NC pins are connected together. Until an object moves on the system and impacts the lever, the lever is pressed close, the NC contact and COM pin will open to interrupt the object's journey.

When there is a pair of NO contacts on the limit switch, the COM pin will now switch to connect to NO, and at the same time output an electrical signal to trigger a certain designed effect such as reversing the rotation direction of the switch motor.

3) What types of limit switches are there?

Today, on the automation market there are many types of limit switches. Each type will have different advantages, limitations and uses.

If classified based on shape, Limit switches can be divided into: push button type, lever type, microscopic type, etc. Classified according to the type of action required, travel limit switches include: operating lever. spring action, lifting action lever, pulling action lever,...

3.1) Classification according to physical structure and shape

3.1.1) Push button limit switch

This push button limit switch usually has a push button at the top of the switch. The device's case and head are made of metal that can withstand physical impacts such as impact. The most common push button type limit switch will be the type with 3 pins and these 3 pins are the contacts of the switch. The push button limit switch has 2 types of contacts:

Moving contacts: The contacts will be connected to the shaft and push button.

Static contact: Located at 3 legs and maintains the same position without change.

When we press the button, the moving contact attached to the button will gradually decrease from one leg to the other, turning on and off the electrical circuits going to the device. Just like that, the devices will stop or operate as soon as we press the button. Push button travel limit switches are mostly used for applications that require a travel length of about 10mm.

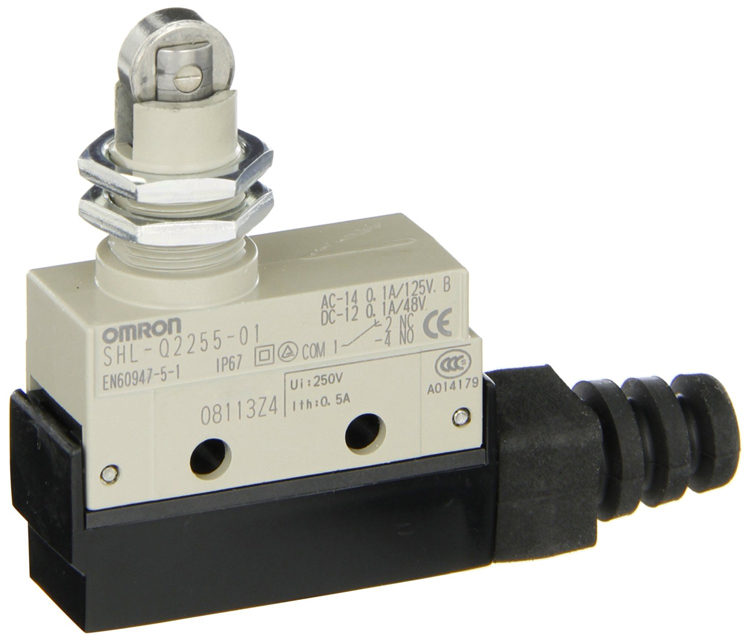

3.1.2) 2-way travel limit switch (microscopic form)

- A 2-way limit switch or micro limit switch is a device with both NO and NC contacts (normally closed/normally open) on the same switch. And because there are 2 NO/NC contacts, this type of switch will have higher accuracy and is often used in cases requiring high travel accuracy (usually from 0.3 ~ 0.7mm).

- The 2-way limit switch includes an impact-resistant metal casing, 2 static contacts and 1 moving contact.

- The moving contact of the microscopic Limit switch will be mounted on the top of a leaf spring (made of a metal leaf, usually elastic aluminum), when the switch button is pressed (this button is attached to a shaft attached). with leaf springs) causes the spring to deform and bounce downward, the moving contact on the spring touches the normally closed static contact (also known as the lower pin) creating a closed circuit, thereby bringing the electrical device into operation dynamic.

- When you let go of the switch, the leaf spring, thanks to its elasticity, returns to its original position. The moving contact mounted on the top of the spring also returns to its original position, causing the circuit to open and the electrical device to stop right at the point trip.

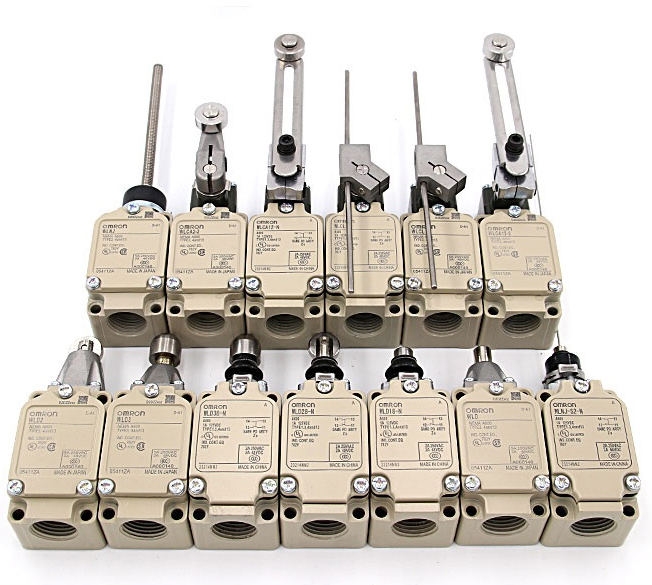

3.1.3) Lever-type limit switch

- Limit switch lever is the most popular type of limit switch in civil and industrial fields. This type of device has 1 NO or NC contact, the default contact is NC (normally closed). With this switch, the actuator arm is designed from the connecting rod to the lever shaft. Even if the rod is misaligned, the drive shaft can still rotate freely.

- In case the force display bar is removed, the lever shaft will be returned to its normal state by the switch through the return spring.

- Below the lever shaft is attached an additional roller. It plays the role of rotating the movement when this part changes position from right to left. Operation of mechanical action with multiple contacts mounted on the limit switch side.

- Initially, the contact design of the switch can be open or closed. The combination of the actuator mechanism with the lever will move the contact from one state to the other. This causes the limit switch to be mainly in the open state and when activated, it will close.

The structure of the lever-type switch is also more complicated than the two types of push-button and subtle limit switches. It includes the following parts:

- Roller

- Blow

- Static contact

- Dynamic contact

- Spring

- Then lock

- Spinning disc

3.2) Classify according to the type of impact needed

3.2.1) Spring limit switch

The spring limit switch is designed with two versions: plastic body and metal body. The plastic body version reaches IP65 while the metal body version reaches IP66 and both can be used well in outdoor activities. The clear difference between spring limit switches compared to other types is that a spring is mounted on the head with the task of receiving impact from the transmission parts.

3.2.2) Wheel head travel limit switch

Lever-type limit switch at the top of the wheel

The limit switch has a body and wheel (roller level) designed with a plastic body. IP67 waterproof standard, operating temperature at 70 degrees Celsius. Operates with maximum voltage of 500vac, rated current of 1A, comes with a pair of fast-acting NO and NC contacts. With two-way impact lever, the product is designed with IEC 947-5-1 standard. Integrated 10A safety short-circuit protection fuse.

Limit switch at the top of the increase wheel

This type of limit switch has a plastic body with IP65 standard. One-way impact type, capable of operating with a voltage of 500VAC, rated current up to 10A, with 1 NO and 1 NC contact.

Use PG13.5 cable gland, operating temperature 70 degrees Celsius. Level 2 electric shock standard, integrated 10A short circuit protection.

3.2.4) Pull action limit switch

Pull limit switch is called in English pull wire emergency stop switch, an electrical device used to turn on and off the operation of the conveyor belt when an incident occurs without having to go directly to the electrical cabinet. Thanks to this remote on/off feature, pull limit switches have been and are being used extremely commonly in many factories.

This type of switch operates by pulling up through the metal ring on top, used in emergency systems or in sliding door applications. Metal body design, IP65 watertight standard, NO, NC 10A quick-acting contact, voltage 500VAC. Operating cycle 3600 times per hour.

Pull limit switches are divided into those with a reset button and those without a reset button.

The pull limit switch has a reset button

The pull limit switch does not have a reset button

In addition to the most popular types mentioned above, limit switches also include a number of other types such as:

- Hanging limit switch

- Spindle limit switch

- Pressure limit switch

- Vertical roller piston limit switch mounted to the electrical cabinet

- Horizontal roller piston limit switch mounted to the electrical cabinet

- Horizontal bar type hinge limit switch

- Long horizontal bar type hinge limit switch with roller

- Long horizontal bar type hinge limit switch with one-way roller

- Good push bar type limit switch

- Roller limit switch rotates the arm

- Adjustable rotary bar limit switch

- Ball head piston limit switch

- Disc lever limit switch

4) Advantages and disadvantages of travel limit switches

|

Advantage

|

Defect

|

|

Compatible with many industrial applications, easy to use and control

Reliable detection of an object regardless of color, shape or size along with precise location and precise repeatability.

Save energy consumption

Able to connect to controllers to expand applications and control more loads.

Not affected by the operating environment, preferred for use in harsh environments

Low investment costs

Easy to maintain and replace when necessary

|

Limited to devices with low movement speeds.

Cannot be used in applications that require hygiene and safety such as food, cosmetics, beverages, etc.

Cannot be used in industries that do not directly touch the object to be detected such as: medical instruments, precision mechanical parts, glass...

Mechanical structures that operate for a long time need periodic maintenance

Easy to disconnect, environments with a lot of vibration also affect the operation of the limit switch

Response ability is slower than other types of sensor devices

Difficult to use for slow, extremely slow moving objects

Direct contact with the device is required to perform on/off

Mechanical parts wear out and are not durable due to direct contact with the equipment

|

5) Application of travel limit switch

Limit switches convert motion into electricity to activate another process in a production or manufacturing line. In fact, limit switches are used in many different production lines and the most popular are lines using compressed air. Besides, they can also be found in:

In civil life

They are used to open and close automatic gates, monitor the journey of elevators, escalators,... with a number of names such as: elevator travel switches, rolling door travel switches,...

In industry

- In the automobile manufacturing industry. The limit switch is used to detect that the vehicle frame is moving on the conveyor belt. Bringing control signals to central systems such as PLC, DCS, SCADA... This is a typical application to save significant costs instead of position sensors, optical sensors, proximity sensors...

- In the transportation industry at seaports, they are used to control cranes to transport containers to the right location...

- In amusement parks, limit switches are used to control the journey of mechanical structures such as ferris wheels, roller coasters, trains, etc.

- In the manufacturing industry, they are used on conveyor belts to change the direction of objects on the conveyor belt, as switching contacts for machine mechanisms, to monitor the journey of robot arms...

Most limit switches are used for the purpose of limiting travel in general, meaning that when the mechanism impacts the switch position, it will cut off the power supply to the structure. More specifically, the role of Limit switch in applications is:

- Count the impact or count the product

- Detects object contact

- Detect range of movement

- Detect the position and movement limits of objects

- Turn off the circuit when there is a problem

- Detects the speed of an object

Below I will go specifically into some of the most common applications of limit switches

Rolling door

Rolling doors are used with the main function of preventing theft. Currently, rolling doors are often installed in homes or factories. Automatic rolling doors consist of an aluminum sheet rolled onto a shaft. This shaft is attached to a bearing and connected to a Servo motor. The limit switch pin is connected to the door motor. When the door is pulled up, the motor will rotate in the same direction. The pull-down door rotates in the opposite direction thanks to 2 limit switches attached to 1 Relay.

Hoist

A hoist is a chain system connected to a pulley. The top of the chain has an iron hook attached to help pull or lift objects and goods up/down. The other end is a chain coil connected to a rotating shaft. This shaft can be attached to a manual rotating lever or to a motor with high traction power. To lift and lower objects and goods, this motor needs to be equipped with a forward and reverse circuit limit switch so that objects and goods can stop at the right time and easily raise or lower the iron hook easy and fast.

Crane

The operation of the limit switch on the crane will be similar to that on the hoist. Crane operators often use buttons to control goods. People will use limit switches for light cranes, which do not need too high precision. This will reduce investment costs compared to using AC or sensors.

Forklift

Forklifts are often equipped with lever-type limit switches mounted inside the driver's compartment. The levers on forklifts that we often see are also used for the purpose of lifting objects (usually heavy goods). The front of the forklift has a motor mounted to raise or lower the lifting shaft, directly connected to 2 Limit switches to bring into the driver's compartment.

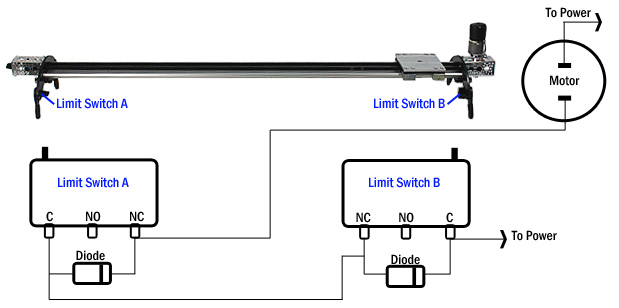

Conveyor

Limit switches are usually attached to the conveyor belt in manual conveyor control mode. When loading goods onto the belt, we need the conveyor belt to stop in the right place. This can absolutely be done using a servo controller, but usually we will use both in parallel because the limit switch helps reverse the rotation direction of the internal motor, thereby reversing the running direction of the conveyor belt. When there is a problem, you need to run the tape in reverse, which is also easy for warranty and repair with just 1 limit switch.

6) Instructions for choosing and buying a limit switch

When choosing a limit switch, we need to note the following points:

Demand

Depending on each application need and the objects that need to be controlled, there will be a type of switch with appropriate limits. For application needs in machinery operating at normal speeds, the basic limit switch is the most suitable choice. Some special cases will require the use of limit switches with rollers. In higher requirements for accuracy, instead of buying a limit switch, you should consider choosing a proximity sensor to put into use.

Drive force

Depending on the force transmitted between the limit switch and the machine, we can choose the most suitable type of transmission mechanism. Specifically:

- If the work load is light or medium, you can choose a limit switch with a shell made of plastic. But if the design has a high load, the shell needs to be made from metal.

- The mover needs to be chosen depending on the shape and direction of movement of the object.

Control circuit voltage

No matter how the control circuit is designed for the nominal voltage and current, the limit switch also needs to be selected accordingly.

Installation environment

When choosing a switch, you also need to pay attention to the installation environment, vibration, shock, humidity, dust, etc. This helps ensure the best and most durable performance of the device.

Whether the limit switch is selected as open type or protected type will depend on its installation environment.

Besides the above notes when choosing a limit switch, you also need to pay attention to a number of points such as: operating speed, minimum force, connection module, cable input module and switch life work...

For example: Currently, rotary lever and piston type limit switches are the most popular.

Rotary levers use various lever arms which, when actuated by an object, rotate on a shaft to operate the switch contacts.

Piston actuators work well for detecting the movement of microscopic machine parts. It has a variety of mechanisms such as: roller piston, metal piston (side or top push) and lever piston. Care must be taken when operating the plunger limit switch, otherwise damage may occur.

7) Instructions for using the limit switch

7.1) Instructions for self-installation of Limit switch

Although limit switches use many types of voltage: 12V, 24V, 220V... but in general, the way these types are connected is not much different.

With a 3-pin limit switch including COM Pin, NO Pin, NC Pin. These three pins are clearly labeled on the switches. If not, we can determine the pin pairs by using VOM meters that measure continuity at the resistance scale. If you measure the COM pin with one of the two pins that make the clock jump, it is the NC pin, and the other pair of pins is definitely the NO pin.

Wiring procedure for travel limit switch in 4 steps:

Step 1: Determine the source for the type of limit switch being used

Step 2: Connect the hot wire (positive wire) to the COM pin

Step 3: Wire the signal to the NO and NC pins according to the circuit design

Step 4: Power up and operate according to the drawing principle

7.2) Reversing circuit using travel limit switch

8) Top 3 highest quality limit switch brands

8.1) Hanyoung travel limit switch

Limit switches of Hanyoung Nux are divided into 2 types:

Limit switch with standard size:

- Operating speed: 0.1-1m/S

- Mechanical frequency: 120 times/minute

- Electrical frequency: 20 times/minute.

- Insulation resistance: 100m (ohm)

- Electrical endurance: 1000VAC 50/60Hz 1 minute.

- Fault-tolerant vibration: frequency 10-55Hz

- Impact mechanical strength: Min 100G

- Collision fault tolerance: Min 30G

- Mechanical life: minimum 1 million impacts

- Electrical life: Minimum 0.3 million impacts

Mini limit switch:

-

- Mechanical frequency: 120 times/minute

- Electrical frequency: 30 times/minute.

- Insulation resistance: 100m (ohm)

- Electrical endurance: 1500VAC 50/60Hz 1 minute.

- Fault-tolerant vibration: frequency 10-55Hz

- Collision mechanical strength: Min 30G

- Collision fault tolerance: Min 10G

- Mechanical life: minimum 1 million impacts

- Electrical life: Minimum 0.1 million impacts

Although Hanyoung limit switches have just entered the Vietnamese market, they are very popular because: Low price and relatively good durability. However, currently the company is limited to a few models and a small consumer market.

8.2) CHINT limit switch

Chint's limit switches are divided into 2 types:

YBLX-ME rod limit switch

Operating voltage, current: 50/60Hz 380Vac 0.8A, 220VDC, 0.16A

Conforms to standards: GB/T 14048.5, iec60947-5-1, CCC China

Small limit switch YBLXW-5

Operating current voltage: 50/60 Hz 380 VAC 0.79A, 220VDc 0.14A

Conforms to standards: GB/T 14048.5, iec60947-5-1, CCC China

You may be interested in: Genuine CHINT limit switch

8.3) Limit switch Omron

Similar to the above two brands, Omron Limit switches are also divided into 2 types: Standard limit switches and mini limit switches.

Omron limit switches have been present very early in the Vietnamese market, are popular in many industries, and have many models with different sizes. Another outstanding advantage is safety and high mechanical life.

9) Where should I buy limit switches?

On the market today, limit switches are being provided by many units, however, not every place commits that the devices they provide are products of clear origin and guaranteed quality.

Understanding these issues, over the years Amazen has been building itself into an address providing quality travel limit switch products with clear origins and competitive prices so that customers can use them with peace of mind.

Therefore, if you have a need, please contact Amazen immediately to be provided with genuine limit switches from Korea and China, 100% new, outstanding quality and complete accompanying certification documents. . With a team of highly specialized technical support and sales consultants, our company is confident that it will bring customers the best purchasing experience.