Precise temperature control for cold storage or incubators is always a difficult problem for technical engineers. However, this problem will be solved if we know how to use the temperature controller properly. So what is a temperature controller? Why is this device so important to thermal control? Next, Amazen would like to send to readers the most understandable knowledge about the structure and function of a common temperature controller.

1. What is a temperature controller?

A temperature controller is a device used to measure, control and control temperature in a certain space and time.

In addition to temperature, this type of control device also has the ability to simultaneously measure and control humidity in closed spaces. With this feature, the temperature regulator becomes an indispensable component in heating systems, plastic injection machines, drying ovens, compressed air systems, ...

In addition to the most common name of temperature controller, mechanical engineers also call them by many other names such as: temperature sensor, temperature meter, temperature control meter, performance meter thermostat, PID temperature controller, digital thermostat, …

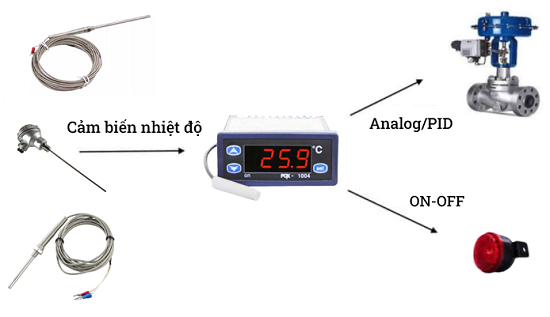

The temperature controller

Normally, after measuring temperature with a temperature sensor or thermocouple, we have 2 ways to monitor and control:

Transmitted to a center such as PLC/DCS for monitoring and control

Insert temperature controller to control

In a single small system that does not use a PLC, temperature sensors will be given top priority because of the versatility and superior efficiency they provide. Diverse sizes, installation methods, ease of use, high precision control and reasonable price are the reasons why temperature calibrated meters are commonly used.

2. Structure and operating principle of the temperature controller

2.1) Structure of temperature controller

The 3 main components that make up a temperature controller are:

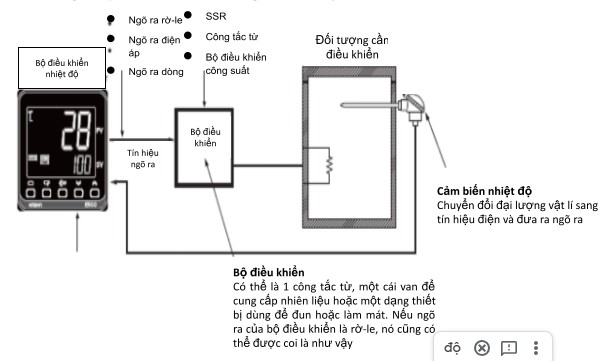

Sensor: With the ability to sense physical, chemical, and biological changes in the environment, the sensor on the heat control meter has the main function of measuring the actual value of temperature, humidity, flow, …and control them. These data are converted by the sensor into signals to be sent to the controller.

Controller: Is the place that will receive and process signals transmitted from the sensor. After receiving the signal, the controller continues to output the processed signal to the control device.

Control device: Receives direction signals from the controller and performs exactly as previously programmed.

Although the thermal controller has a compact size, it plays the role of the brain of the control process. Sensors are considered eyes and control devices are considered human limbs when operating. These 3 components work together to help the thermostat operate most accurately.

Structure of the temperature controller

2.2) Operating principle of temperature controller

In principle, the temperature controller first measures the ambient temperature (process variable), then compares it with the desired temperature value (set value). The difference between these values is called error (deviation). Based on this error, the controller will decide how much heating or cooling is needed to bring the temperature to the desired value. Completing this process, the controller sends an output signal (operation value) that affects the required change. The output signal is typically connected to a heater, control valve, fan, or some "final control element" that actually pumps or removes heat from the process.

2.3) Wiring diagram for temperature controller

Below is how to wire a thermostat using a PT100 3-wire thermal probe, specifically the VX4-UCMA-A1CT from Hanyoung Nux.

Sensor: Connect the 3 wires of the PT100 temperature probe to 3 digital pins 10, 11 and 12

Power supply: Connect the 220V AC power supply to pins 5 and 6

3) Temperature controller specifications

There are countless types of temperature controllers in use today, but they generally have the following specifications:

- Power supply: 85~265 VAC, 24VDC Option. The most common would be the 220V temperature controller

- Power consumption: 4AV

- Input input: K, J, R, S, B, E, N, T, W, PL2, U, L, PT100, JPT100, JPT50.

- Voltage input: 0-1V, 0-5V, 0-10V, 1-5V, 2-10V, -10-10mV, 0-10mV, 0-20mV, 2-50mV, 10-50mV.

- Current input: 0-20mA, 4-20mA.

- PID control output: SSR, 0-10VDC, 0-5VDC, 4-20mA, Relay, Servo valve, Heat Cool mode.

- Accuracy level: 0.2 percent F.S.

- Operating temperature: 0-50 °C.

- Transmitter: 4-20mA, 0-20mA, maximum load resistance: 560Ω, 0-5V, 0-1V, 1-5V, 2-10V,

- Maximum load current: 20mA.

- Communication: MODBUS, RS232, RS485, TTL.

- Baudrate: 38400, 19200, 9600, 4800, 2400bps.

-

4) What control modes does the temperature controller have?

If the temperature controller's main task is to measure and control heat, then the 3 main control modes of this type of device are:

4.1) PID control

A temperature controller with PID self-control function helps adjust the temperature automatically without human intervention during installation.

PID control is a form of control that specializes in providing proportional derivatives combined with integration. It controls respectively 2 additional adjustments. One part helps the units automatically compensate with the system, on the other hand, it creates a smooth combination between the components in the controller.

PID control is mainly applied in systems with large transmission capacity and frequently changing frequency. At times like these, the controller will help compensate for the amount of energy caused by the changes.

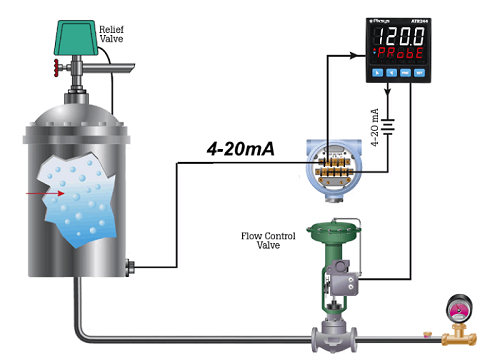

Water level control by PID

The controller can run fully automatically without human intervention, the following is required:

The controller receives 4-20mA signal and outputs 4-20mA PID.

4-20mA water level sensor.

The water control valve discharges a 4-20mA signal

– Water level measured from the sensor, called process variable (PV)

– SV is the desired setting value

Water level control by PID

4.2) ON/OFF control

It can be easily seen that this is the simplest control mode, has been used for a long time and is still widely used in many different industries.

The advantage of this mode is that the control is simple and easy to understand. However, it has the disadvantage of not having high accuracy and high overheating causing energy loss.

The operating principle of ON/OFF mode is quite simple: the controller will impact the output if the measured ambient temperature exceeds the set value (Can be impacted when within the delay range without needing to the set value - if the user has a hysteresis range setting). And usually, the ON/OFF mode will correspond to the control output type which is Relay type.

4.3) Proportional temperature control

I personally feel this is the most useful function of a temperature controller. With this function, the controller will control proportionally eliminating cycles related to on/off control. In simpler terms, when the ambient temperature is close to the set point, proportional control will reduce the amount of energy supplied to the A/C.

5) What types of temperature controllers are there?

Temperature controllers will be classified into:

5.1) Programmable temperature controller

This type of temperature controller will work according to a preset program, maintaining the heat level for the set time period and switching to another heat level. Users can program up to 16 different heat segments with the program starting from ambient temperature or from 0°C depending on the purpose of use.

5.2) The temperature controller connects to the computer via RS485 communication

For temperature controllers with integrated RS485 communication port, through the software connected to the computer, the value parameters, alarm, output percentage of the meter will be displayed and can also be set put okay.

Users manage and monitor these values in the form of excel files, column charts, and graphs. And most importantly, it is possible to change the parameters of the temperature sensor right on the software.

5.3) DIN Rail temperature controller

Thermal control types installed directly on the Rail are divided into 2 types: types with integrated push buttons right on the controller and types that require an external screen with a 1m long cord.

The DIN Rail temperature regulator, when integrated with the Transmitter, will be used as an extremely effective signal converter. Diverse input types of temperature, signal, ... converted to analog signals and up to 2 relay outputs. Input and output signals are easily adjusted via buttons on the temperature sensor.

6) Advantages of temperature controller

- In my opinion, some of the most outstanding advantages of the temperature controller include:

- Assists in operating equipment in a safer manner

- Helps reduce energy consumption

- Assists in maintaining thermal comfort (heater, oven,...) and also humidity

- Good monitoring for the system.

- Reduce human resources costs

- Helps clearly identify maintenance problems (abnormal temperature drops...)

7) Application of temperature controller

- Temperature display and controller are used in many fields and industries, from industrial factories to civil production activities.

- The most common application is poultry incubators from mini to large capacity, helping to control and adjust the pressure furnace temperature to be neither too high nor too low.

- Monitor and control the temperature of kilns and ceramic kilns with temperatures up to thousands of °C. This field requires extremely high temperature accuracy. Once there is a temperature deviation, the entire batch of baked goods will be damaged.

- In addition, temperature control meters are also used for residential air conditioners, radiator fans in manufacturing plants, dryers, ovens, boilers, etc. We also have a separate article about the application. Uses of drying oven temperature controllers.

8) Which brand of temperature controller is reputable?

Currently, many temperature controller brands are offered in the automation equipment market. However, through the process of research and practical use, below I will mention 3 brands that, in my opinion, are of the best quality.

8.1) Autonics temperature controller

Autonics' temperature control devices are considered to be capable of responding at a high speed and quickly reaching the user's desired value. The display accuracy of this brand's heat meter is extremely small, only from ±0.1% to ±0.3%.

The Autonics temperature sensor is designed with multiple outputs, diverse control modes, easy and user-friendly. Many industries need this type of product, such as food processing lines, plastic extrusion, greenhouse systems, waste treatment, product packaging,...

Refer to Autonics temperature controller at: https://amazen.com.vn/dong-ho-nhiet/autonics.html

8.2) Hanyoung temperature controller

Temperature calibration meters from the manufacturer Hanyoung mostly use LCD screens, the temperature error is extremely small. In particular, this brand's products also have the ability to independently adjust temperature and humidity and have a high safety warning system. With diverse inputs, suitable for many types of devices and modern communication functions, Hanyoung's thermal sensors have long been the optimal choice of a large number of consumers in the Vietnamese market.

Buy genuine Hanyoung temperature controller at: https://amazen.com.vn/dong-ho-nhiet/hanyoung.html

8.3) Conotec temperature controller

The Conotec digital thermostat controller is also considered a good choice. This device operates with high display accuracy of ±0.3%, has many types of inputs: function to select temperature, voltage and current sensors, many auxiliary outputs: LBA, SBA, 7 Alarm outputs , RS485 communication output.

Conotec thermostats help reduce energy consumption, maintain thermal comfort and monitor systems incredibly well.

Conotec temperature controller good price at: https://amazen.com.vn/dong-ho-nhiet/conotec.html

Epilogue

In case you need to learn, need technical advice and order temperature controller products, please contact Amazen immediately via:

Hotline: 0934 399 068 - Sales: 0938 072 058

Email: amazen@amazen.com.vn

With a team of highly specialized technical support and sales consultants, our company is confident that it will bring customers the best purchasing experience.

Amazen commits that all inverter products we currently offer are genuine, 100% brand new, quality guaranteed and fully accompanied by CO/CQ and VAT certification documents.