The DSFOX-TP10 temperature controller is widely used in automation technology. In highly precise automation processes where minimizing errors is crucial, the DSFOX-TP10 temperature gauge is a trusted choice. It takes on the critical tasks of monitoring and regulating both temperature and humidity, ensuring stable and reliable operation of machinery. This makes it an invaluable tool for maintaining efficiency and preventing downtime in automated systems.I. The product information DSFOX-TP10

1. The overview about DSFOX-TP10

.jpg)

ĐThe Conotec DSFOX-TP10 temperature controller is a device designed to regulate temperature in industrial applications. It is part of the DSFOX product line from Conotec, offering precise and flexible temperature control features. Here are some key features of the DSFOX-TP10:

Accurate Temperature Control: The device uses a PT100Ω sensor to measure temperature with high accuracy, making it suitable for applications that require tight temperature control.

Flexible Control Outputs: The DSFOX-TP10 comes with a control relay (1NO + 1NC) and a warning relay, allowing you to easily set up different control modes, such as cooling or heating.

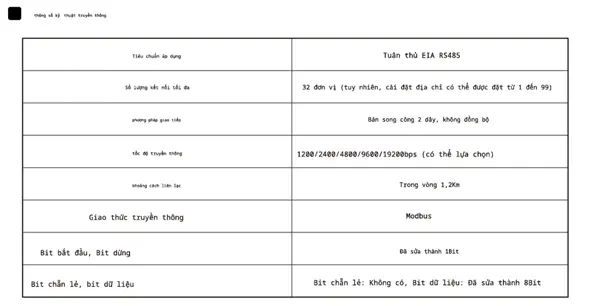

RS485 Communication: The device supports MODBUS 485 communication, enabling easy integration into automation systems and remote monitoring.

Time Delay Settings: You can configure a time delay for the outputs, helping protect the device and system from sudden temperature fluctuations.

Temperature Calibration: The temperature calibration function ensures the accuracy of measurements and control, allowing for fine-tuning of temperature settings.

Wide Temperature Range: The DSFOX-TP10 can measure and control temperatures ranging from -200°C to 400°C, making it suitable for a variety of industrial applications.

With these features, the DSFOX-TP10 offers reliable and versatile temperature control, ensuring stability and efficiency in industrial systems that require precise thermal management.

2. DSFOX-TP10 in deployment fields

The Conotec DSFOX-TP10 temperature controller is widely used in various industrial and domestic sectors thanks to its ability to provide accurate and flexible temperature control. Below are some of its key applications:

Food Industry:

Ovens and Steamers: Controls temperature to ensure food quality and safety.

Freezers and Refrigerators: Maintains stable temperatures for food preservation.

Chemical Industry:

Chemical Reactions: Controls temperature during chemical reactions to ensure performance and safety.

Chemical Storage Tanks: Monitors and adjusts temperature to prevent unwanted reactions.

Plastic Industry:

Injection Molding Machines: Controls the temperature of the mold to ensure product quality.

Extrusion Machines: Adjusts the temperature to ensure smooth extrusion processes.

Textile Industry:

Dyeing Machines: Controls temperature during dyeing to achieve the desired fabric color and quality.

Drying Machines: Adjusts temperature to dry fabric without damaging the material.

Domestic Applications:

Heating and Cooling Systems: Controls temperature in HVAC systems to maintain a comfortable living environment.

Home Appliances: Used in devices like microwaves and coffee machines to regulate temperature.

Electronics Industry:

Testing and Experimentation: Used in laboratories to test and experiment with electronic devices at different temperatures.

With its versatility and precision, the DSFOX-TP10 is an excellent choice for temperature control in a wide range of applications, from industrial processes to everyday household appliances.

II. The wiring and connection map DSFOX-TP10

1. Sensor PT100

PT100 is a type of temperature sensor, commonly referred to as a PT100 sensor or PT100 temperature sensor. The name "PT100" comes from two components: Pt, which stands for Platinum, and 100, which represents the resistance value of the sensor at 0°C, i.e., 100Ω.

1.1. Structure and how PT100 carry on

The PT100 consists of a platinum probe, which is protected by a protective casing and connected to signal wires. Common types of PT100 sensors can have 2, 3, or 4 wires for different purposes, depending on the accuracy and application requirements.

The PT100 works based on the principle that the resistance of platinum changes with temperature. As the temperature increases, the resistance of platinum also increases in a linear manner. This change in resistance allows for accurate temperature measurement.

1.2. PT100 in deployment fieldsPT100 sensors are widely used in various industrial and domestic fields due to their high accuracy and durability. Below are some of the key applications:

Food Industry:

Ovens and Steamers: Measure and control temperature to ensure food quality and safety.

Freezers and Refrigerators: Maintain stable temperatures for food preservation.

Chemical Industry:

Chemical Reactions: Control temperature during chemical processes to ensure performance and safety.

Chemical Storage Tanks: Monitor and adjust temperature to prevent unwanted reactions.

Plastic Industry:

Injection Molding Machines: Control the temperature of the molds to ensure product quality.

Extrusion Machines: Adjust the temperature to ensure smooth extrusion processes.

Textile Industry:

Dyeing Machines: Control temperature during dyeing to achieve the desired fabric color and quality.

Drying Machines: Adjust temperature to dry fabric without damaging the material.

Domestic Applications:

Heating and Cooling Systems: Control temperature in HVAC systems to maintain a comfortable living environment.

Home Appliances: Used in devices such as microwaves and coffee machines to regulate temperature.

2. RS485 main tranform to USB

The RS485 to USB converter is a device that converts signals from the RS485 standard to a USB port, allowing devices that use RS485 communication to connect to a computer via the USB port. This tool is particularly useful in industrial and automation applications, where remote monitoring and control are required.

2.1. The characteristics RS485 to USB

Easy Connection: This device can be directly connected to a computer via the USB port, with no external power supply required as it draws power from the USB port.

Supports Multiple Operating Systems: It is compatible with various operating systems, including Windows, Linux, and MacOS, making it versatile and easy to integrate into different environments.

High Data Transmission Speed: The converter supports baud rates ranging from 300 to 921600 bps, allowing fast and stable data transmission, ensuring efficient communication.

Safety Protection: It comes equipped with built-in protection features such as Electrostatic Discharge (ESD) protection, Over-voltage Protection (TVS), and Short-circuit Protection, ensuring safe operation and protecting connected devices from electrical damage.

Multiple Device Communication: The converter can communicate with multiple RS485 devices simultaneously, supporting up to 32 devices on the same bus, making it ideal for larger systems and networks requiring multi-device communication.

This RS485 to USB converter offers an easy, reliable, and safe solution for connecting RS485 devices to computers, making it an essential tool for industrial automation and remote monitoring applications.

2.2. Tranform cable RS485 to USB in deployment fields

Industrial Monitoring and Control: Used in systems for monitoring temperature, humidity, and other environmental parameters to ensure stable and safe operation in industrial settings.

Automation Systems: Connects devices such as PLC, sensors, and controllers to a computer for remote monitoring and control, enabling streamlined automation and real-time data collection.

Testing and Experimentation: Used in laboratories for testing and experimenting with electronic devices under different conditions, ensuring their functionality and reliability.

Security Systems: Connects access control devices and security surveillance systems to computers for centralized monitoring, management, and data analysis to ensure safety and security.

These applications make the RS485 to USB converter an essential tool in industries where remote communication, monitoring, and control of multiple devices are required for optimal performance and safety.

2.3. How to installation and set up for RS485 to USB

For older operating systems like Windows 7 or XP, you need to manually install the driver for the RS485 to USB converter. However, newer operating systems (like Windows 10 or later) typically auto-detect the device and install the necessary drivers automatically..

3. Warning light Schneider

3.1. The overview about warning light Schneider

Code product: XA2EVM6LC

Manufacturing brand: Schneider

Color: Blue

Dimension : Ø22mm

Voltgate: 220V

Standard: CCC, CE

III. Activity principle of DSFOX-TP10

The Conotec DSFOX-TP10 temperature controller has two main operating modes: cooling mode and heating mode. Below is the operating principle for each mode:

1. Cooling mode

Operating principle: When the measured temperature exceeds the set value, the control relay will activate to turn on the cooling system (such as a fan or air conditioner). When the temperature drops below the set value, the relay will trip to turn off the cooling system.

Application: This mode is often used in industrial cooling systems, refrigerators, and devices that need to maintain low temperatures.

2. Heating mode

Operating principle: When the measured temperature is lower than the set value, the control relay will activate to turn on the heating system (such as a heater or heater). When the temperature rises above the set value, the relay will trip to turn off the heating system.

Application: This mode is often used in industrial heating systems, ovens, and devices that need to maintain high temperatures.

IV. The installation of temprature controller DSFOX-TP10

1. The installation of temprature controller DSFOX-TP10

1.1.Basic installation

Temperature setting: You can set the desired temperature value for both modes using the control buttons on the watch face.

Temperature Calibration: The device allows the current temperature to be calibrated to ensure the accuracy of measurements.

Time delay: You can set a time delay for the output to protect the device and system from sudden temperature changes....

1.2. Directly example

In a cooling system: If you set the temperature to 25°C, when the measured temperature exceeds 25°C, the cooling system will turn on. When the temperature drops below 25°C, the system will turn off.

In a heating system: If you set the temperature to 20°C, when the measured temperature is lower than 20°C, the heating system will turn on. When the temperature rises above 20°C, the system will turn off.

2. Detail instructing

2.1. Display screen

2.2. Basic button

2.3. Menu specification

2.4. Video Instructing install of inventer curcuit

V. Usage instructing of DSFOX, Kepserverex 6 cùng winCC

DSFOX software, because this product does not yet support DSFOX-TP10 encryption, I use Kepserverex 6 software combined with Wincc Flex for communication.

Install specification

Note line 30101 display temprature clock

Basic display of systemVideo Usage instructing of DSFOX, Kepserverex 6 cùng winCC

Closing remarks

In case you need to learn, need technical advice and assembly for the temperature control circuit, please contact Amazen immediately via:

Hotline: 0934 399 068 - Sales: 0938 072 058

Email: amazen@amazen.com.vn

With a team of highly specialized technical support and sales consultants, our company is confident that it will bring customers the best purchasing experience.

Amazen commits that all inverter products we currently provide are genuine, 100% new, quality guaranteed and complete with accompanying CO/CQ and VAT certification documents.