What is motor? What is the structure of the motor? What is its operating principle? Today, Amazen will explain everything about the motor's information through the article below!

1. What is motor?

Motor (French: Moteur, English: Motor) is a device that creates motion like an engine, it is often used to refer to an electric motor or an internal combustion engine. This part is a generator used to convert electrical energy to mechanical energy. The electrical machine used to convert the reverse (from mechanical to electrical) is called a generator or dynamo. Common motors - electric motors used in homes such as electric fans, refrigerators, washing machines, water pumps, vacuum cleaners,...

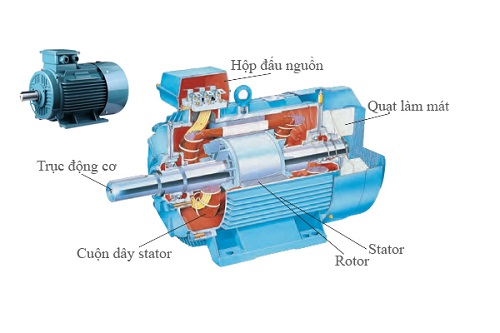

Actual Motor image

2. Structure of the motor

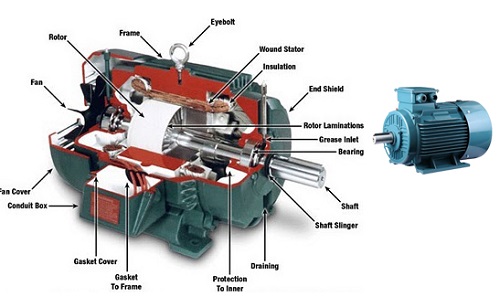

The structure of the electric motor when asynchronous will depend on the type of casing and cooling system. With the cover, there are 2 types: closed and open. As for the cooling system, the ventilation fan is placed inside or outside the electric motor. In short, the Motor has two main parts: the static part and the rotating part.

Structure of Motor

The static part is also known as the stator. Consists of two main parts: steel core and winding wire.

Steel core

It is a hollow cylindrical part with a magnetic conduction function for the machine. The steel core is made of technical steel sheets with a thickness of 0.35 to 0.5 mm. The steel core is made in the shape of a scarf, the inside has a groove to fit the winding wire and is painted before being assembled.

Winding wire

The winding wire is made of copper or aluminum placed in the grooves of the steel core.

In addition to the steel core and winding wire, there is also an additional part that covers the steel core, which is the machine case. It is made of aluminum or cast iron used to hold the steel core tightly. At the bottom is a base to securely attach to the machine base. The two ends have two caps made of the same material as the case. Inside the cover there is a bearing used to support the rotor's rotating shaft.

Motor rotating part

The rotating part of the motor is also called the rotor, consisting of a steel core, winding wire and machine shaft

Steel core

The steel core has a solid cylindrical shape, made of electrical engineering steel sheets. They are stamped into a disc shape and pressed tightly. There are grooves on the surface to fit the winding wire. The steel core is tightly coupled to the rotating shaft and placed on two stator bearings.

Winding wire

The winding depends on the rotor type. Currently on the market there are two types: squirrel cage rotor and wound rotor.

The wound rotor has the same winding system as the stator. This type has the advantage of large rotating torque. The disadvantage is that the structure is complex and the price is relatively high.

Squirrel cage rotor: The winding structure of this rotor is very different from the winding structure of the stator. It is made by casting aluminum into the grooves of the rotor. From there, aluminum bars are created and short-circuited at both ends. A special feature is that it has additional fan blades molded to cool the inside when the rotor rotates.

The winding part is made from aluminum bars and two short-circuit rings shaped like a cage, so it is called a squirrel cage rotor. The grooves on the rotor are usually stamped obliquely to the shaft, to improve the opening characteristics and reduce vibration caused by electromagnetic forces acting intermittently on the rotor.

3. Operating principle of Motor

For the motor to work, the motor's stator needs to be supplied with alternating current. At this time, the current is responsible for flowing through the stator winding to create a rotating magnetic field at a speed of n=60. f/p (rpm)

In there:

f: Frequency of the power source.

p: Number of pole pairs of the stator winding.

During rotation, the magnetic field will sweep through the rotor bars, causing an induced electromotive force to appear. The current-carrying bars in the magnetic field will interact with each other, creating an electromagnetic force that is then placed on the guide bars. At this time, the electric force will create a torque for the rotor shaft, causing the rotor to rotate in the direction of the magnetic field. In addition, the rotor has a working speed smaller than the magnetic field, so the rotor will rotate slowly, so it is called an asynchronous motor.

Operating principle of the motor

Principle of operation

The main part of the electric motor (electric motor) consists of a stationary part (stator) and a moving part (rotor) that are wound with many turns of wire or have permanent magnets. When the coils on the rotor and stator are connected to the power source, magnetic fields exist around it. The magnetic field interaction of the rotor and stator creates rotation of the rotor around the axis or a torque.

Most electric motors (electric motors) operate on the principle of electromagnetism, but motors based on other principles such as electrostatic force and voltage effect are also used. The basic principle on which electromagnetic motors are based is that there is a mechanical force on a current-flowing coil located in a magnetic field. This force is as described by the Lorentz force law and is perpendicular to the coil and also to the magnetic field.

Most magnetic motors are rotary, but there are also linear motors. In a rotary motor, the moving part is called the rotor, and the stationary part is called the stator.

4. Classification of motors

Classification of electric motors is based on two basic criteria: Current and actual operation

Classified by current

Single phase electric motor

This type of stator winding has only 1 phase winding and the power supply will include 1 cold wire and 1 phase wire and an additional capacitor to shift the phase. However, this device only has 1 phase coil, so the circuit's magnetic field is a 1-phase magnetic field, so it cannot be turned on.

In order for the device to turn itself on, users will need many different methods combined. This type of single-phase electric motor is often used for winches, hand tools, air compressors...

3 phase electric motor

When the 3-phase alternating current begins to pass through the stator winding, a rotating magnetic field (RMF), also known by its full name, Rotating Magnetic Field, will appear. Therefore, current will be generated inside the guide bars of the squirrel cage rotor and it will eventually rotate.

3 phase electric motor

Classification in practice

Synchronous motor

Synchronous motors are quite special when the rotor rotates at the same speed and magnetic field as the stator. This type is currently divided into:

+ Independently excited asynchronous motor: Meaning it uses the same principle as a magnetic motor.

+ Directly excited asynchronous motor: Uses 1 permanent magnet to operate.

Asynchronous motor

Any motor that operates on the principle of electromagnetic induction is classified as asynchronous. The slower rotation speed of the rotor and the slippage between the rotation speed of the magnetic field demonstrate its asynchronous nature during mechatronic operation.

An asynchronous motor has a rotating component (rotor) that is simulated similar to a squirrel cage. In addition, asynchronous motors also use coils to reduce the pressure from the motor's starting current thanks to resistors connected directly into each coil.

5. Advantages of motors

- Has very wide applicability, not only in industrial factories but also in workshops or households with familiar equipment.

- Affordable price, easy to find and buy at stores.

- Diverse voltage sources used such as AC or DC, many different sizes and types.

- Work completely automatically and independently.

- Users can repair, replace gears, shafts or rewind copper wires when damaged.

- Depending on each job requirement, buyers can choose a slow-rotating or fast-rotating motor.

6. Application of motor

Electric motors are used in many areas of human life, not just in production.

For example, electric motors with smaller sizes will be used in the production of household electrical appliances such as: rotating washing machine drum, rotating dishes in microwave oven, dishwasher, spinning CDs in disc player. , turn the fan blade in the fan or turn the drill bit...

Electric motors are widely used in machinery systems and production lines in mechanical factories, electronic component assembly, automobile manufacturing, finished product packaging, food processing, chemicals, fertilizers, etc. fodder…

In addition, electric motors are also widely used in the field of transportation and freight transport with motor vehicles and trains using electric motors to operate cost-effectively and effectively.

Motor application

7. Common errors in electric motors

Even if it is a quality or genuine device, over a long period of use, it will still encounter problems and errors. Amazen will list common errors so you can identify and fix them below:

- The power source is out of phase

- The electric motor works a lot, causing heat

- The device makes loud noise

- 3-phase electrical cabinet cannot be controlled

- Unstable running, sometimes running and sometimes stopping

- Smell the burning smell of the device when the power source is short-circuited

Common errors in Motor

8. Simple motor maintenance instructions

- In order for the electric motor to operate durably at the highest capacity, users need to regularly maintain the electric motor properly. Some notes when maintaining electric motors are as follows:

- Regularly monitor the sound of the machine during operation

- Check the temperature of the electric motor during operation

- Check electrical energy consumption with an ammeter

- Check the contact of fuses, circuit breakers and other starting points

- Clean the outside of the electric motor to avoid dust and water

- Regularly maintain the electric motor according to the manufacturer's recommendations

9. Top reputable motor brands to use

Motor Toshiba

Toshiba Motor is a reliable and stable product, a product of a Japanese technology company. Highly reliable Toshiba motors have improved motor quality, reduced power consumption, low noise, high durability and long-term stability.

Motor Toshiba

Basic technical specifications of Motor Toshiba

- Voltage: 220/380V For Frame size 160L and Less, 380/660V For Frame size 180M and above

- All have cooling fans installed

- Protection level: IP55

- Insulation level: F

- Body material: Frame size 71 and 80M Steel, Frame size 90L~160L: Aluminum, Frame size 180M and above: Cast Iron

- Ambient temperature: -10 – 40°C

- Humidity: 90% or Less

- Standard: IEC 60034-1 / IEC 60034-5

- Capacity from 0.37kW (0.5HP) to 45kW (60HP) 2-pole, 4-pole, 6-pole structure

Technical characteristics of Motor Toshiba

- Reliable bearing manufacturer, Toshiba chooses bearing manufacturers from Japan and EU to help increase engine life

- Innovative design increases engine performance, operating costs and low noise

- Improved insulation, making the motor operate more efficiently

- The product has reduced size and weight, while still ensuring engine reliability and efficiency

- Low motor noise and long lasting cooling fan

Where to supply genuine, quality Toshiba Motor: https://amazen.com.vn/thuong-hieu/toshiba/motor.html

Motor Transmax

Transmax is a strong brand that has been supported by customers for over 20 years, providing a wide range of engines and transmissions. . . The design is increasingly improved in science and quality to help increase product life. Our products offer very high reliability during the manufacturing process.

Asynchronous motor: Transmax motor has a simple and powerful design. Transmax products in Vietnam are always available in a variety of designs and are manufactured according to IEC standards.

Basic technical specifications of Transmax 3-phase electric motor

- Speed: 1000 rpm/ 1500 rpm/ 3000 rpm

- Capacity: 0.18KW - 315 KW

- Mounting type: Base/flange

- Aluminum/cast iron housing

- Speed reducer: for heavy and light loads

- Gearbox: gear ratio 5 - 200

Motor Transmax

For details, refer to Motor Transmax at: Thiết bị điện công nghiệp Amazen

Motor Hitachi

Specifications

- Power: 1HP = 1 horse = 0.75kw, pole speed, 4 poles: 1400-1500 rpm, 2 poles: 2800 - 3000 rpm, 6 poles: 900-1000 rpm.

- Current: voltage exported to Southeast Asia: 380V, frequency 50Hz

- Rated ampere current represents the large voltage that can be operated

- Engine code: TKO-KK (base), VTFO (flange_

- Operating mechanism: S1 (shows 24h/24h continuous running), IP55 (shows dust and water protection level), IC411 (full cooling mode, has both fan blades and upper heatsinks motor body)

Motor Hitachi

Advantages of 3-phase Hitachi Motor

- High efficiency, usually reaching 95% or more

- Stable rotation speed, suitable for industrial requirements

- Long lifespan, usually 5-7 years

- Stable quality, modern technology

- Reasonable price

See more information about Motor Hitachi at: https://amazen.com.vn/motor/hitachi.html

Motor SGP

SGP electric motor, also known as SGP motor, is a type of 3-phase asynchronous electric motor, manufactured according to European technology and production lines. SGP Motor meets the international standard IEC 60034-30:2008 with completely closed structure, optimized structure, low noise, high strength dust and water resistance, protective layer and insulation layer high heat, the outer shell is made of aluminum and cast iron specialized for the industrial industry, so this is the perfect choice for businesses and factories.

Specifications

| Wattage |

0.18KW-315KW

|

|

Frame size

|

63M-355L

|

|

Round tassels

|

2P~2800rpm/ 4P~1450rpm, 6P~960rpm, 8P~720v/p

|

|

Voltage

|

1 phase 220V |

|

Frequency

|

50/60Hz

|

|

Protection level

|

IP 55

|

|

Heat resistant grade

|

F(155)

|

| Operating time |

S1 (continuous) |

|

Ambient temperature

|

From -15ºC to 40ºC

|

| Load core |

11mm – 95mm

|

|

Wire material

|

100% copper |

|

Shell material

|

Aluminum/cast iron |

|

Mounting type

|

Bracket/flange/base + flange |

Motor SGPBuy SGP Motor at good price and quality at: https://amazen.com.vn/motor/sgp.html

Motor Tunglee

Specifications

- Popular capacity: 200W, 400W, 0.75kW, 1.5kW, 2.2kW, 3.7kW

- There are also mini speed reduction motors: 6W, 15W, 25W, 30W, 40W, 60W, 90W, 120W, 150W

- Most commonly used ratios: 1/20, 1/30, 1/40, 1/50, 1/60

- Design type: coaxial, perpendicular, negative core

- Precise mechanical processing, compact, diverse installation positions, manufactured using Taiwanese technology

Motor Tunglee

Advantages of Motor Tunglee

- Easy to install, save space and optimize machine performance

- There are many types of motors and many types of speeds and torque levels to choose from

- High durability and longevity, minimizing maintenance and repair costs

- Tunglee engine company applies advanced manufacturing technology and uses high quality materials, helping the motor operate smoothly and minimize noise.

- Tunglee motor company provides high quality products at reasonable prices, helping to save initial investment costs and minimize operating costs during use.

Epilogue

Above is all the most important and basic content about the Motor product line. Hopefully the article content will assist you in the process of learning, choosing to buy and operate this line of automation equipment.

In case you need to buy a semiconductor relay or have any questions or need further advice, please contact Amazen via:

Hotline: 0934 399 068 - Sales: 0938 072 058

Email: amazen@amazen.com.vn

With a team of highly specialized technical support and sales consultants, our company is confident that it will bring customers the best purchasing experience.

Amazen commits that all glass relay devices we currently provide are genuine, 100% brand new, quality guaranteed and fully accompanied by CO/CQ certification documents.