The transformer is an indispensable device in modern electrical systems, playing an important role in transmitting and distributing electricity from the place of production to the place of consumption. With the ability to change voltage, transformers help optimize the power transmission process, minimize power loss and ensure the safety of electrical equipment.

In the context of rapid technological development and increasing demand for energy, understanding the structure, operating principles and practical applications of transformers is very important. This article will introduce transformers in detail, from their structure, operating principles to common applications in the fields of industry, civil and renewable energy. At the same time, we will mention famous brands such as CHINT and LightStar, along with their transformer products, to help you have an overview and make the right choice for your needs. Join Amazen to explore the world of transformers and better understand the role this device plays in building an efficient and sustainable power system.1. What is a transformer?

A transformer or transformer is a static electromagnetic device, operating on the principle of electromagnetic induction, used to change the voltage system with an unchanged frequency.

In a transformer, changing the voltage can only be done when the current is alternating or pulsed. Transformers are used in power transmission and distribution systems, and are also applied for many other purposes such as connecting rectifier circuits, providing power to electric furnaces, welding machines, testing machines... A transformer has two or more windings wound on a common magnetic circuit, which may or may not be electrically connected to each other.When they are electrically connected together, it is called an autotransformer.

2. Structure of the transformer

The transformer has a general structure including the following main components:

Magnetic core (Core):

• Steel core: Made from thin sheets of electrical engineering steel, laminated together to reduce losses due to eddy currents. The magnetic core enhances the efficiency of the electromagnetic induction process.

• Structure: Usually E or U shaped for easy placement of winding coils.

Windings:

• Primary winding: Receives input voltage from the source and creates a variable magnetic field in the magnetic core.

• Secondary winding: Receives a changing magnetic field from the primary winding and creates an output voltage. The number of turns of the secondary coil determines the output voltage.

• Material: Usually made of copper wire or aluminum wire with insulation.

Enclosure:

• Material: Usually made from steel, aluminum or insulating materials.

• Function: Protects internal parts from the effects of the external environment such as dust, moisture, and mechanical impacts.

Insulating Oil:

• Function: Cools and insulates the components inside the transformer. Insulating oil is often used in large transformers.

Auxiliary components:

• Voltage regulator (Tap changer): Used to adjust the output voltage of the secondary coil, helping the transformer operate stably.

• Cooling system: Can be a fan, oil pump or other heat dissipation system to keep the operating temperature of the transformer at a safe level.

• Protection devices: Includes protective relays, lightning arresters and fuses to protect the transformer from overload and short circuit incidents.

Insulation:

• Insulating materials: Includes insulating paper, insulating plastic or other composite materials to insulate between coils and between coils and magnetic core.

• This structure helps the transformer operate effectively in voltage conversion and ensures safety when used in electrical systems.

3. Operating principle of transformer

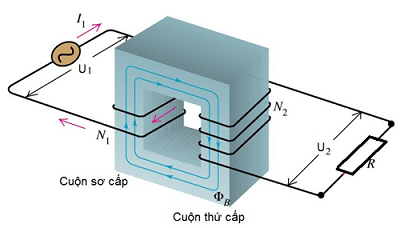

The transformer operates according to two physical phenomena:

- Electric current flowing through a wire creates a magnetic field

- The change in magnetic flux in the coil creates an induced voltage (electromagnetic induction phenomenon)

Operating principle of transformer

- Coil N1 and coil N2 are wound on a closed steel core. Apply an alternating voltage U1 to coil N1, on this coil a current I1 will flow in the wire, and at the same time a magnetic flux will appear in the wire for both coils N1 and N2. Coil N2 is connected to the load, then on coil N2 there will be current I2 with voltage U2. Thus, the energy of alternating current has been transferred from winding 1 to winding 2.

4. Practical applications of transformers

Transformers have many important practical applications in electrical and industrial systems. Here are some key applications:

Power transmission and distribution:

• Voltage Boost: Transformer helps increase voltage to high levels to transmit power over large distances, helping to reduce losses due to wire resistance.

• Voltage reduction: At distribution stations, transformers reduce voltage to a level that is safe and suitable for consumers such as families and businesses.

Industry:

• Electric furnace power supply: The transformer supplies high voltage to the electric furnace, which is used in metallurgy and steel production.

• Welding machines: Transformers provide a stable power source for industrial welding machines.

Electronics and telecommunications:

• Powering electronic devices: Small transformers are used in power supplies to convert voltage to suit electronic devices such as computers, TVs, and telecommunications equipment.

• Circuit isolation: Ensure safety by isolating input and output circuits in electronic devices.

Medical:

• Medical equipment: Transformers provide stable and safe power for medical equipment such as X-ray machines, MRI machines, and other diagnostic equipment.

Recycled energy:

• Wind and solar power: Transformers help convert and transmit electricity from wind and solar power systems into the national grid.

Transportation:

• Railway: Provides power to the electrified railway system, helping to operate electric trains.

Ứng dụng dân dụng:

• Stable voltage: Transformers in voltage stabilizers (UPS) help maintain stable voltage and protect household electrical appliances.

Transformers play an important role in ensuring efficiency and safety in the transmission, distribution and use of electricity in many different areas of life.

5. Classification of transformers

Like many other electrical devices, there are many ways to classify transformers:

• According to structure, we will divide into single-phase transformer and three-phase transformer

• According to function, there are low voltage transformers and step up transformers

• According to insulation method: oil core transformer, air core transformer,…

• According to the winding relationship, we divide it into autotransformer and induction transformer

• By task: power transformers, transformers for civil use, welding transformers, pulse transformers,…6. Popular transformer brands on the market

CHINT brand transformerCHINT is one of the leading manufacturers in the field of electrical equipment, including products such as transformers, switchgear, control systems, and many other types of electrical equipment. CHINT transformers are known for their high quality, outstanding performance and reliability in industrial and residential applications.

Outstanding features of CHINT transformers:

• High quality: CHINT transformers are manufactured according to international standards with strict quality testing procedures, ensuring the product is highly durable and operates stably for a long time.

• Superior performance: Using advanced materials and technology, CHINT transformers achieve high efficiency, reducing power loss and optimizing operating efficiency.

• Product diversity: CHINT provides many different types of transformers, from small transformers used in electronic devices to large transformers used in power transmission and distribution systems.

• Safety and reliability: The design and construction of CHINT transformers ensure safe operation, with overload, short circuit and good insulation protection features.

Buy CHINT transformers at: https://amazen.com.vn/bien-ap/chint.html

LIGHTSTAR brand transformerLightStar is a famous brand in the field of transformer manufacturing, providing high quality and reliable products for a variety of applications. With a commitment to quality and advanced technology, LightStar transformers have been widely used in power systems worldwide.

Outstanding features of LightStar transformers:

• Advanced technology: LightStar transformers are manufactured with advanced technology, using premium materials and modern manufacturing processes, ensuring optimal power conversion efficiency and high durability.

• High quality and reliability: LightStar products comply with international standards for quality and safety, ensuring stable and reliable operation throughout their life.

• Energy saving: With optimal design, LightStar transformers help minimize power loss and save energy, contributing to environmental protection and reducing operating costs.

• Easy installation and maintenance: The smart design of LightStar transformers allows for easy installation and maintenance, helping to reduce the time and cost of maintenance and repairs.

• Product diversity: LightStar offers a wide range of transformers suitable for a variety of applications, from small transformers for electronics to large transformers for transmission and distribution systems Electrical Power.

For details, refer to the LightStar transformer at: Amazen industrial electrical equipment

EpilogueTransformers play an indispensable role in modern power systems, helping to ensure efficient transmission and distribution of electricity from generating sources to consumers. With the continuous development of technology, brands such as CHINT and LightStar have continuously improved products to meet the increasing market demands for performance, reliability and safety.

From providing stable electricity for industrial parks and residential areas, to applications in renewable energy, transformers have been making an important contribution to the sustainable development of the global power system. Choosing high quality transformers from reputable brands will help optimize operating efficiency, minimize power loss, and ensure the safety of the electrical system.

Hopefully, with the information and knowledge shared in this article, you will have a clearer view of the role, applications and product lines of transformers, thereby making decisions. Be wise about your needs. Thank you for your interest and following!In case you need to buy a Transformer, or have any questions or need further advice, please contact Amazen via:

Hotline: 0934 399 068 - Sales: 0938 072 058Email: amazen@amazen.com.vnWith a team of highly specialized technical support and sales consultants, our company is confident that it will bring customers the best purchasing experience.

Amazen commits that all glass relay devices we currently provide are genuine, 100% brand new, quality guaranteed and fully accompanied by CO/CQ certification documents.