HANYOUNG VX4-UMNA-A1C TEMPERATURE CONTROLLER AND OTHER DEVICES CONTROLLED IN PID MODE

Hanyoung VX4-UMNA-A1C temperature controller is an electronic device designed to manage and regulate temperature in industrial systems precisely through PID control. This controller possesses many outstanding features that help optimize temperature control, including high accuracy, flexible settings and user-friendly interface. PID control provides more precise control, minimizing temperature fluctuations and increasing energy efficiency, thereby improving product quality and machine durability. Let's learn with Amazen how to connect and operate the Hanyoung VX4-UMNA-A1C Temperature Controller in PID control through the article below!I. Select equipment in the temperature control system

1. Protective switching devices

Basic technical specifications of MCB CHINT NXB-63 2P C20 6kAProduct code | NXB-63 2P C20 6kA |

Rated operating voltage | 220/230/240V, 400/415V |

Frequency | 50Hz |

Rated impulse withstand voltage Uimp (kV) | 4KV |

Electricquota | 20A |

Cutting line | 6KA |

Mechanical switching life | 20.000 times |

Electrical contact switching life | 10.000 times |

Ambient temperature | -5℃ ~ 40℃ |

For details, refer to MCB CHINT NXB-63 2P C20 6kA at: https://amazen.com.vn/cb-tep-mcb-nxb2-20-dong-cat-6ka-2-cuc.html

2. Type K temperature sensor

Parameters Samil wire type K thermocoupleProduct code | TW-N-K-0.1-25M |

Product's name | Type K thermocouple |

Diameter | Ø6 mm |

Material | SUS 304 |

Thermal threshold | 0-600℃ |

Length | 100mm |

Wire length | 1m |

Thread size | Ren 13 |

3. Warning device

General introduction of the HY-256-MA Siren product

The HY-256-MA siren is a device that signals an error in the electrical system, helping workers and supervisors to handle equipment errors when there is a problem emitted by the horn.

• The LED lights up when the bridge is broken

• Compact design with 3 built-in melodies

• There is an LED display on the front when the horn is operating

• Easy to install on the cabinet

• Low power consumption

HY-256-MA technical specificationsType | Code | Describe |

HY - | | | 3 tones electronic buzzer |

Dimension | 226 | | Ø22 / Ø25 dual usage (Rectangular shaped front) |

256 | | For Ø25 installation (Round shaped front) |

| Power supply voltage | MD | 12 - 24 V d.c |

MA | 100 - 240 V a.c |

Dimension siren HY-256-MA 4. Omron MY2N-GS AC220/240 intermediate relay

Detailed technical specificationsTransparent case | Yes |

With mechanical indicator | Yes |

Mounting method | With plug-in socket |

Usage | General purpose |

Poles | 2 |

Rated carry current | 7 A |

Coil voltage | 230 V |

Operation voltage | AC |

Contact material | Ag |

Contact description | DPDT |

Features | LED |

Terminal | Plug-in, Solder |

Dimensions and pinout of Omron MY2N-GS AC220/240 Intermediate Relay 5. Temperature control meter VX4-UMNA-A1C

VX4-UMNA-A1C code selection table and technical specificationsModel | Code | Content |

VX | | | | | | | | | | | | LCD Digital Temperature Controller |

Size | 2 | | | | | | | | | | | 48(W) × 96(H) × 63(D) ㎜ |

4 | | | | | | | | | | | 48(W) × 48(H) × 63(D) ㎜ |

7 | | | | | | | | | | | 72(W) × 72(H) × 63(D) ㎜ |

9 | | | | | | | | | | | 96(W) × 96(H) × 63(D) ㎜ |

| Sensor | U | | | | | | | | | | Universal input |

| OUT 1 (control output 1) | M | | | | | | | | | Relay output |

S | | | | | | | | | Voltage pulse output (voltage pulse output for SSR drive) |

C | | | | | | | | | Current output (4-20 mA current output for SCR drive) |

| OUT 2 (control output 2) | N | | | | | | | | None |

M | | | | | | | | Relay output |

| Power | A | | | | | | | 100 - 240 VAC 50/60 Hz |

D | | | | | | | 24 VDC |

| Sub output | A1 | | | | | | 1 relay output (VX4 basic option) |

A2 | | | | | | 2 relay outputs (VX2, VX7, VX9 basic option) |

A3 | | | | | | 3 relay outputs (※ *1,*2) |

A4 | | | | | | 4 relay outputs (※ *2) |

| Communication | | | | | | None |

C | | | | | RS-485 communication |

| Retransmission output (RET) | | | | | None |

T | | | | Retransmission output (4 ~ 20 mA) |

| Digital input (DI) | | | | None |

D2 | | | 2 digital inputs (DI 1 ~ 2) |

D4 | | | 4 digital inputs (DI 1 ~ 4) |

| Current detection input (CT) | | | None |

H1 | | Current detection input (CT) 1 contact |

H2 | | Current detection input (CT) 2 contacts |

| Remote input (REM) | | None |

R | 1 input, 4 ~ 20 mA (1 ~ 5 V) |

Dimensions and pinout of VX4-UMNA-A1CII. How to install the controller

1. Alarm warning in “High-Low deviation” mode

See how to set Alarm warnings in "High-Low deviation" mode at: INSTRUCTIONS FOR INSTALLING HANYOUNG VX4-UMNA-A1C TEMPERATURE CONTROLLER

2. PID control algorithm

What is PID algorithm?

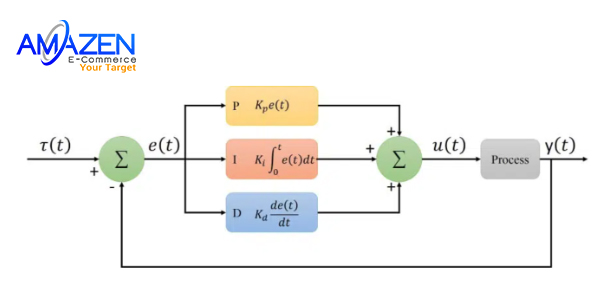

PID stands for Proportional, Integral and Derivative. This is a control method in which the deviation (error) between the desired value and the actual value is used to regulate the process.

Operating principle of PID

PID operates based on three main components: proportional (P), integral (I) and derivative (D). Each of these components contributes a distinct function to the controller, helping to optimize and maintain the process in the desired state.

P (Proportional) Component

The proportional component reduces the error response rate and is the first component considered in a PID controller.

Component I (Integral)

The integral component accumulates error over time and increases the response strength, eliminating long-term error.

Component D (Derivative)

The derivative component predicts the future of the error, helping to slow down the system response to avoid overshooting.

• Actuator (heating device)

• Installed control devices such as screen HMI or PLC.

• Feedback devices include pressure and temperature sensors...

Once you have selected the set point value, which we often call SV set value, the controller will send control information to each actuator and structure.

In this process, there will be a series of algorithms that require continuous opening and closing with slow or fast times depending on the system being worked.

For example, in a chart, the control temperature is always at 200 degrees F. The on - off level is continuously opened and closed at 202 degrees F, 198 degrees F. This is to ensure the temperature is always 200 degrees F. maintained at the set level.

Benefits of using PID

Using PID brings many significant benefits to automation systems:

• Process optimization: PID helps keep the process operating at a high level of efficiency, minimizing errors and responding quickly to any changes in operating conditions.

• Energy and cost savings: By precisely adjusting parameters, PID helps reduce energy consumption and operating costs.

• Improved durability and stability: PID-controlled systems are less likely to fail and become damaged due to overload or unstable operation.

Application of PID (Proportional Integral Derivative)

The use of Proportional Integral Derivative in industry is now very popular, they participate in processes: production, machining, processing... in many different industries and fields.

The device helps reduce fluctuation errors as well as setup time, overshoot... effectively. Accordingly, there are many applications that use PID such as:

• Using inverter control: Electrical and electronic equipment with PID helps form inverter control.

• Used to control water level: PID devices are used to help automate sensitive and flexible electrical and electronic equipment, sensors, and valves. This helps bring high productivity.

• Used in systems with PLCs: With PID control devices, users can design built-in functions to help provide the ability to adjust heat, pressure, flow...

• Besides, PIDs can also control water flow thanks to pipe sensors. This is one of the outstanding advantages when it comes to watering this device.

It can be seen that PID controllers are extremely necessary in our current lives. They are widely used in people's daily lives. 3. Video instructions for installing VX4-UMNA-A1C temperature controller with PID control

Above are our instructions on how to use and how to install the PID controlled Hanyoung VX4-UMNA-A1C temperature controller. Hopefully this information will be useful to you in the process of learning and using this device.

In case you need to buy the VX4-UMNA-A1C Temperature Controller or have questions or need further advice, don't hesitate to contact Amazen via:

Hotline: 0934 399 068 - Sales: 0938 072 058

Email: amazen@amazen.com.vn

With a highly specialized team of technical support and sales consultants, our company is confident that it will bring customers the best purchasing experience.

Amazen commits that all temperature controller products we currently offer are genuine, 100% brand new, quality guaranteed and with full certification documents accompanied.