Limit switch, also known as Limit switch, is an indispensable device in the industrial automation industry. With the ability to control and monitor machine movements, limit switches ensure the production process takes place accurately and safely. In this article, we will explore what a limit switch is, its operating principle, common types of limit switches and their applications in industry. If you are looking for an effective solution to improve the performance and reliability of your automation system, let's learn more about limit switches in the sections below.

1. What is a limit switch (Limit switch)?

- Limit switch is a type of electromechanical device used to limit the travel of moving parts in a certain structure or system. It has the same structure as a normal electrical switch except that it is equipped with an additional lever so that the moving parts will change the state of the contact inside it when impacted. When no longer active, the limit switch will automatically return to its original position.

- Limit switch is an electromechanical device used to control the operation of machinery and automation equipment. Limit switches operate by detecting the position of a mechanical part through a moving mechanism, such as a lever, roller, or lever. When the mechanical part moves to a certain position, it acts on the limit switch, activating or disconnecting the electrical circuit, thereby controlling the operation of the machine.

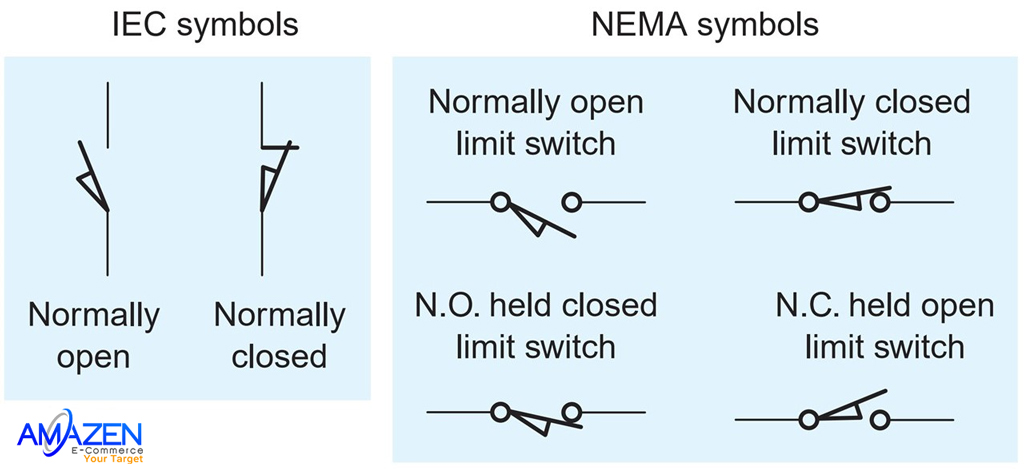

Symbols of limit switches in technical drawings

2. Structure and operating principle of limit switch (Limit switch)

Structure

A limit switch will be composed of the following parts:

- Transmission receiver:

The transmission receiver plays an extremely important role in a limit switch. This part is what makes the difference between Limit switch and regular switches. They are mounted on the top of the limit switch and perform the task of receiving impact from moving parts to activate the switch.

- Switch body:

The limit switch body contains an electrical contact mechanism, including components located inside a plastic shell, which functions to minimize damage caused by impact to protect the electrical circuit inside the switch.

- Connection pin (Socket/Plug):

The connection pin is where the screw terminals of the contact are located to connect to the wiring system. This is considered the output signal part for the switch because it is responsible for transmitting signals to other devices when affected by a certain transmission part.

Principle of operation

Limit switches operate based on the basic principle of detecting a change in position or movement of a mechanical part, thereby activating or disconnecting the electrical circuit to control the operation of the machine. Below is a detailed description of the operating principle of the limit switch:

• Moving mechanism: Limit switches are usually equipped with a moving mechanism such as a lever, lever, roller or push button. When a part of the machine moves to a certain position, it will impact this mechanism.

• Activate the switch: When the moving mechanism is actuated, it will move and act on a contact inside the limit switch. This contact can be normally open (NO - Normally Open) or normally closed (NC - Normally Closed).

• Closing or disconnecting an electrical circuit: Impact on the contact will change the state of the circuit. If the contact is normally open, it will close and allow current to pass through when impacted. On the contrary, if the contact is normally closed, it will break the circuit when impacted.

• Feedback and control: The signal from the limit switch will be sent to the control system, thereby executing subsequent commands such as stopping the machine, changing the direction of motion, or activating another process. This helps ensure the production process goes according to plan and prevents possible problems.

Practical example: A common example is in automated production lines. Limit switches are installed at key locations to detect when a product has passed a certain stage. When the product acts on the limit switch, it sends a signal to the control system that the product is ready for the next stage.

3. Types of limit switches (Limit switch)

Currently, on the automation market there are many different types of limit switches. Each type has its own advantages, disadvantages and uses.

If classified based on shape, limit switches can be divided into: push button type, lever type, microscopic type,... If classified by type of action, limit switches include : spring action lever, increasing action lever, pulling action lever,...

Classify limit switches according to shape and physical structure

Push button form

- This push button limit switch has a push button at the top of the device. Its case and head are made from durable metal, capable of withstanding physical impacts such as impact. The most common push button limit switch has 3 pins, these are the contacts of the switch. Push button limit switches have two types of contacts:

• Moving contact: Attached to shaft and push button, moves when push button is pressed.

• Static contact: Placed on three pins of the switch, remaining in position without change.

- When the button is pressed, the moving contact will move from one pin to another, closing and disconnecting the electrical circuits connected to the device. Therefore, the devices will stop or operate as soon as the button is pressed. Push button limit switches are often used in applications that require a travel length of about 10mm.

2-dimensional form (microscopic form)

- 2-way limit switch also known as micro limit switch, is a device with both NO (normally open) and NC (normally closed) contacts on the same switch. Due to the two NO/NC contacts, this switch has higher precision and is often used in applications that require high travel accuracy, usually from 0.3 ~ 0.7mm.

- 2-way limit switch includes impact-resistant metal casing, two static contacts and one moving contact. The moving contact of a micro limit switch is mounted on top of a leaf spring made from elastic metal, usually aluminum. When the switch button is pressed, the leaf spring is deformed and bounces downward, causing the moving contact to touch the normally closed static contact, creating a closed circuit and activating the electrical device.

- When releasing the switch button, the leaf spring will return to its original position thanks to elasticity, causing the moving contact to separate from the static contact, causing the circuit to open and the electrical device to stop at the desired travel point.

Push lever limit switch

- Lever limit switches are one of the most popular types of limit switches in civil and industrial fields. This type of switch has a NO (normally open) or NC (normally closed) contact, with the default contact being NC. The switch's drive arm is designed from a connecting rod combined with a lever shaft, allowing the drive shaft to rotate freely even when the bar is misaligned. When the force acting on the bar is removed, the lever shaft will return to its normal state thanks to the return spring.

- Under the lever shaft, a roller is added to help rotate the movement when the position changes from right to left. Lever limit switches have multiple contacts mounted inside to facilitate mechanical operation.

The contact design of this switch can be in an open or closed state, and the combination of the actuator mechanism and the lever will switch the contact point from one state to another. This causes the limit switch to normally be in an open state and only close when activated.

- The structure of a lever limit switch is more complicated than that of push button and micro switches, including the following main parts:

• Roller

• Lever

• Static contact

• Dynamic contact

• Springs

• Lock key

• Spinning disc

With its smart design and high reliability, lever limit switches are widely used to ensure performance and safety in industrial and residential applications.

Classified according to the type of impact needed

Lever-type limit switch at the top of the wheel

The limit switch at the top of the roller lever, also known as the limit switch with body and wheel (roller lever), is designed with a plastic case that meets IP67 waterproof standards, withstanding maximum operating temperature of 70 degrees Celsius. The device operates with a maximum voltage of 500VAC, rated current of 1A, and has a pair of fast-acting NO and NC contacts. With a two-way tripping lever, the product complies with IEC 947-5-1 standard and integrates a 10A safety short-circuit protection fuse.

Limit switch at the top of the increase wheel

- The limit switch at the top of the tank wheel is a limit switch with a plastic body meeting IP65 standards. This device operates with one-way operation, voltage up to 500VAC and rated current 10A, with one NO contact and one NC contact. The switch uses PG13.5 cable gland, can withstand maximum operating temperature of 70 degrees Celsius and meets level 2 electric shock standards, with integrated 10A short circuit protection.

- Both types of wheel end limit switches are designed to meet the strict requirements in industrial environments, ensuring high durability and safety. They are the ideal choice for applications that require reliability and consistent performance.

- Pull limit switch, also known as pull wire emergency stop switch, is an electrical device used to turn on and off the operation of the conveyor belt when an incident occurs without having to directly access the electrical cabinet. Thanks to the remote on/off feature, pull limit switches are becoming popular in many factories.

- This device operates by pulling up through the metal ring on the top, commonly used in emergency systems or sliding door applications. With a metal body design that meets IP65 watertight standards, the pull limit switch has NO and NC quick-acting contacts with a rated current of 10A and voltage of 500VAC. Its operating cycle can be up to 3600 times per hour. There are two main types of pull limit switches: those with a reset button and those without a reset button.

In addition to pull limit switches, there are many other types of limit switches such as:

• Suspension limit switch

• Rotary limit switch

• Pressure limit switch

• Vertical roller piston limit switch mounted to the electrical cabinet

• Horizontal roller piston limit switch mounted to the electrical cabinet

• Hinged bar type limit switch

• Long horizontal bar type hinge limit switch with roller

• Long horizontal bar type hinge limit switch with one-way roller

• Good push rod type limit switch

• Rotating arm roller limit switch

• Adjustable rotary bar limit switch

• Ball head piston limit switch

• Disc lever limit switch

With a variety of types and functions, limit switches are the optimal choice to ensure safety and high performance in industrial automation systems.

4. Application of limit switch (Limit switch)

Below are some common applications of limit switches:

Application in conveyor systems

Limit switches are widely used in conveyor systems to monitor and control movement. When the conveyor reaches its final position or there is a problem, the limit switch will automatically cut off power, helping to prevent accidents and protect equipment.

Application in industrial machinery

In industrial machinery such as presses, cutters, and presses, limit switches play an important role in determining the position of moving parts. This helps ensure the production process is accurate and safe.

Application in automatic door system

Limit switches are used in automatic door systems to determine the open/close position of the door. When the door reaches its final position, the limit switch will cut off power to prevent the door from continuing to move, ensuring user safety.

With diverse and important applications, limit switches are an indispensable device in many fields, ensuring safety and efficiency for systems and equipment. If you are looking for a reliable solution for your applications, consider using a limit switch to achieve the best performance.

5. Popular limit switch brands

Limit switch of Hanyoung company

Hanyoung limit switches is a reputable brand from Korea, specializing in providing high quality limit switches with a variety of designs, sizes and specifications, meeting the needs of diverse uses. Rich in the industries of automation, manufacturing, packaging, transportation, construction, etc.

Advantages of Hanyoung limit switches:

• High quality: Manufactured with modern processes, using high-quality materials, ensuring durability and stable operation in harsh environments.

• Diversity: Providing many types of limit switches with different designs, sizes, and specifications, meeting all usage needs.

• Reasonable price: Competitive price compared to other brands on the market.

• Easy to use: Simple and convenient to install and use.

Some popular Hanyoung limit switch product lines:

• HY-M series: Metal body limit switch, compact size, high durability, suitable for applications in harsh environments.

• HY-L series: Plastic body limit switch, cheaper price, suitable for common applications.

• HY-LS series: Compact, space-saving limit switches, suitable for applications with limited installation area.

Omron limit switch

Omron limit switch is one of the world's leading limit switch brands, from Japan. Omron provides a variety of limit switches with high quality, durability and stable performance, meeting diverse usage needs in many industries such as automation, manufacturing, and packaging. , transportation, construction, etc.

Advantages of Omron limit switches:

• Premium quality: Manufactured with modern processes, using high-quality materials, ensuring durability and stable operation in harsh environments.

• Diversity: Providing many types of limit switches with different designs, sizes, and specifications, meeting all usage needs.

• High accuracy: Accurate and reliable operation, ensuring effective control in the system.

• Long lifespan: Can withstand millions of switching times, ensuring long-term use.

• Waterproof and dustproof: Some product lines have good water and dust resistance, suitable for outdoor applications or harsh environments.

• Power saving: Low power consumption, contributing to saving operating costs.

• Easy to use: Simple and convenient to install and use.

Some popular Omron limit switch product lines:

• Z series: Compact, space-saving limit switches, suitable for applications with limited installation space. • WL Series:• A variety of model options are available, including over-travel models with greater OT, models equipped with indicators to check operation, low temperature models, heat-resistant models and corrosion-resistant models.

• Small capacity model added to product line.

• Approved standards: EC/IEC, UL, CSA, CCC (Chinese standards).Limit switch of CHINT brandCHINT limit switches are one of the key products of CHINT group, one of the world's leading electrical equipment suppliers. Designed with high quality standards, CHINT limit switches meet the rigorous requirements of many industrial and civil applications.

Outstanding features:

• High durability: CHINT limit switches are manufactured from high quality materials, enhancing the durability and longevity of the device. They are able to endure harsh environments, resistant to water, dirt and impact.

• High precision: With its sophisticated operating mechanism, CHINT limit switches ensure high accuracy in determining the position of moving parts. This helps optimize the production process and ensure the safety of equipment and users.

• Easy installation and use: The design of the CHINT limit switch allows for easy installation and integration into existing systems. Standard NO and NC contacts make connection simple and flexible.

• International certification: CHINT limit switches have achieved many international certifications for quality and safety such as CE, UL, and RoHS, ensuring they meet global standards.

Some popular CHINT limit switch product lines:

• YBLX-WL series: Compact size, saves installation space, suitable for applications with limited area. Offering a variety of styles, sizes and specifications.

Understanding the limit switch and its structure will help you choose the right type of device to suit your needs, ensuring the system operates effectively and safely. With the continuous development of technology, limit switches are increasingly improved in quality and features, becoming an indispensable part of modern automation processes.In case you need to learn, need technical advice and order a Limit Switch, please contact Amazen immediately via:

Hotline: 0934 399 068 - Sales: 0938 072 058

Email: amazen@amazen.com.vn

With a team of highly specialized technical support and sales consultants, our company is confident that it will bring customers the best purchasing experience.

Amazen commits that all inverter products we currently offer are genuine, 100% brand new, quality guaranteed and fully accompanied by certification documents.